Where Should You Place Non-Potable Water Signs? Site-by-Site Guide

Why Proper Placement of Non-Potable Water Signs Saves Lives

Non-potable water signs are essential safety markers that prevent accidental consumption of water that's unsafe for drinking, cooking or washing. These critical warning signs serve as the first line of defence against waterborne illness and contamination incidents across Australian worksites, public facilities, and commercial properties.

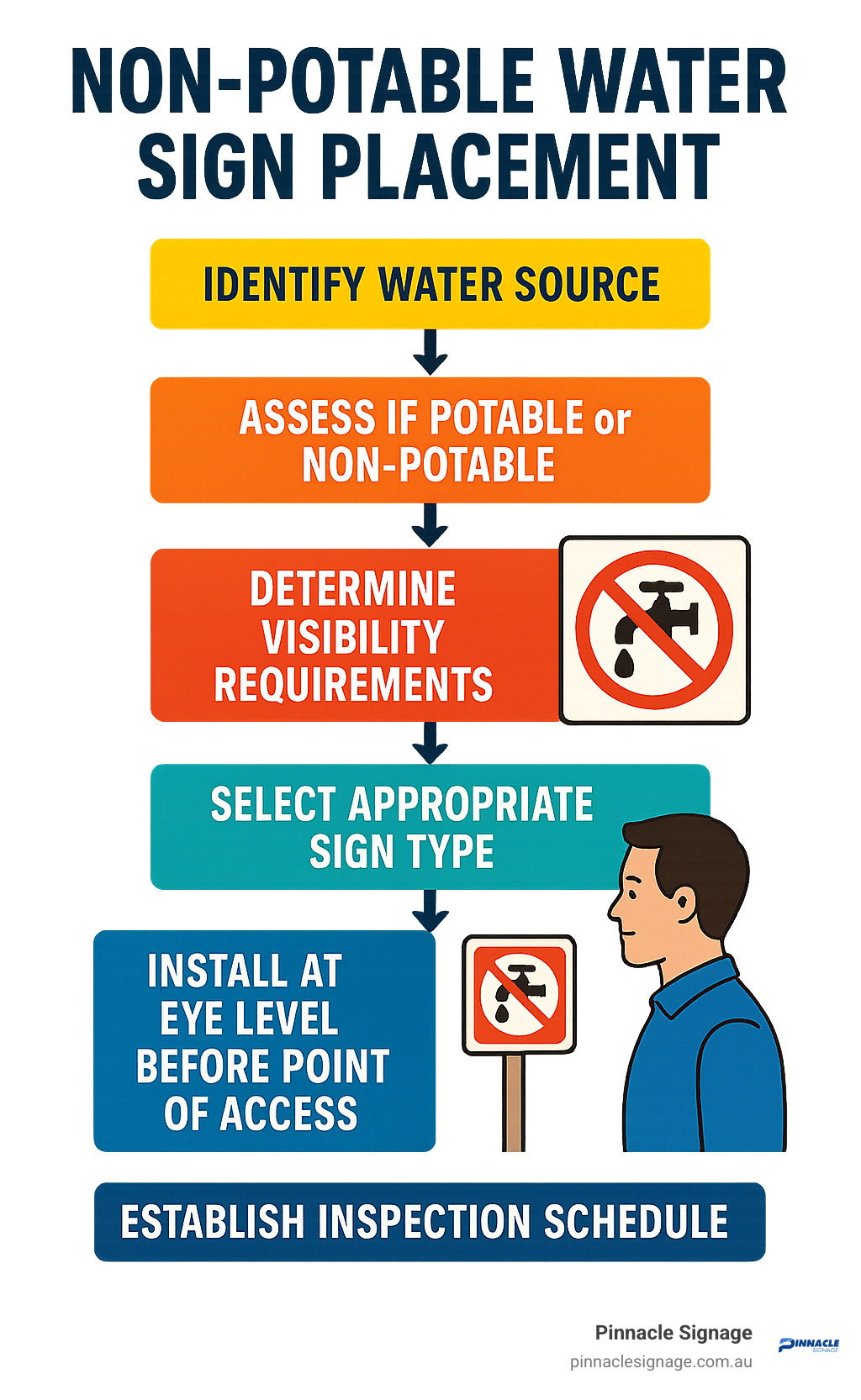

The placement of these signs requires strategic thinking and comprehensive site assessment. Here's where they must be positioned:

• Every non-potable outlet - taps, hose bibs, storage tanks, and filling points • Before point of access - visible before someone can use the water • At eye level or point of use - where workers and visitors will naturally look • High-traffic areas - where temporary staff or contractors might encounter non-potable sources • Plant rooms and behind-the-scenes - where maintenance crews work with dual plumbing systems • Emergency access points - where first responders might encounter water sources during incidents • Maintenance zones - areas where equipment servicing requires water system interaction • Visitor pathways - routes where unfamiliar personnel might encounter unmarked water sources

Non-potable water isn't safe for human consumption but serves many critical purposes across Australian worksites and facilities. It's commonly used for irrigation, dust suppression, concrete mixing, industrial processes, cooling tower operations, and equipment washdown. The water may contain treated wastewater, greywater, bore water, recycled sources, or industrial process water that hasn't met drinking water standards established by the Australian Drinking Water Guidelines.

Understanding the health risks associated with non-potable water consumption helps explain why proper signage placement is so critical. These water sources can harbour harmful bacteria like E. coli, Legionella, and Salmonella, along with chemical contaminants, heavy metals, and other substances that cause serious illness even from brief exposure. Symptoms can range from mild gastrointestinal upset to severe dehydration, organ damage, and in extreme cases, life-threatening complications.

Clear signage isn't just good practice - it's legally required. OSHA regulation 29CFR 1910.141(b)(2)(1) mandates that all non-potable water outlets must be clearly marked to indicate the water is unsafe for drinking, washing, cooking, or food preparation. Beyond legal compliance, proper signage protects your organisation from liability and fulfils your WHS duties to keep workers and visitors safe. Insurance claims, WorkCover investigations, and potential prosecution under workplace health and safety legislation make comprehensive signage a critical risk management investment.

The financial implications of inadequate signage extend far beyond the cost of the signs themselves. A single incident involving non-potable water consumption can trigger extensive medical treatment costs, lost productivity from worker illness, regulatory investigations that disrupt operations, and potential legal action that damages your organisation's reputation. The relatively small investment in comprehensive non-potable water signs provides enormous protection against these costly scenarios.

This comprehensive guide breaks down exactly where to place non-potable water signs across different industries and environments. From agricultural irrigation systems spanning thousands of hectares to construction dust suppression tanks that move daily, we'll cover the high-risk spots that facilities managers and supervisors often miss. We'll also explore the specific challenges faced by different industries and provide practical solutions for maintaining effective signage in harsh Australian conditions.

I'm Doug Lindqvist from Pinnacle Signage, and through years in the safety and industrial supply space, I've seen how proper placement of non-potable water signs prevents serious health incidents across Australian worksites. This practical guide will help you identify every location where these critical safety signs are needed, select appropriate materials for your specific environment, and establish maintenance routines that keep your signage effective over time.

Non-Potable Water Signs: General Placement Rules

Getting non-potable water signs placement right isn't rocket science, but there are some fundamental rules that'll save you headaches down the track. Whether you're running a cattle station in Queensland or managing a high-rise in Melbourne, these principles apply across the board and form the foundation of any effective water safety signage strategy.

Visibility trumps everything else. Your signs need to catch someone's attention before they can access the water source - not after they've already turned the tap on. We typically recommend mounting signs at eye level, around 1.5 to 1.8 metres high, or positioning them directly next to taps, valves, and outlets. I've seen too many well-intentioned signs mounted so high they might as well be invisible, or tucked behind equipment where only maintenance crews will spot them.

The "line of sight" principle is crucial here. When someone approaches a water source, your sign should be visible from their natural approach path. This means considering multiple viewing angles, especially around large installations like storage tanks or complex piping systems. A sign that's perfectly visible from the main walkway might be completely hidden when someone approaches from a service road or emergency access point.

Australian conditions demand tough materials. Our harsh UV exposure and temperature swings will destroy cheap signage faster than you can say "non-potable." Quality signs made from 55 mil plastic or laminated vinyl can handle temperatures up to 75°C and provide reliable service for five-plus years outdoors. It's a small investment that prevents the embarrassment of faded, cracked signs that look unprofessional and fail their safety purpose.

Material selection becomes even more critical in coastal environments where salt spray accelerates corrosion, or in industrial settings where chemical exposure can degrade standard plastics. Aluminium composite signs with protective coatings offer excellent durability in these challenging conditions, while maintaining the clarity and contrast needed for effective safety communication.

Following AS 1319 standards keeps your signage consistent and legally compliant. The standard specifies everything from symbol requirements to colour schemes and text formatting. Your signs should feature bold lettering with high contrast - typically black text on white or yellow backgrounds works best. For mandatory signs, stick to a minimum lettering height of 20mm on signs measuring at least 20cm x 30cm.

The standard also addresses mounting height, viewing distance, and illumination requirements for different applications. Understanding these specifications helps ensure your signage meets regulatory requirements while providing maximum safety benefit. Non-compliance can result in regulatory penalties and increased liability exposure if incidents occur.

Bilingual signage isn't mandatory across Australia, but it's worth considering if you've got multicultural teams on site. English-Spanish combinations work well in many industries, though symbols and pictograms often communicate more effectively than text anyway - especially with children and visitors who might not read English fluently.

The effectiveness of pictograms cannot be overstated. A clear "no drinking" symbol with a crossed-out glass or person drinking transcends language barriers entirely. These universal symbols work particularly well in facilities with rotating contractor crews, international visitors, or emergency responders who might not be familiar with your specific water systems.

Don't forget that purple plumbing identification under AS 2700 provides an additional visual cue. All non-potable water fixtures and piping should be purple, creating a colour-coded system that reinforces your signage strategy. This dual approach - colour coding plus clear signage - creates redundant safety measures that significantly reduce the risk of confusion or accidents.

Why Every Outlet Needs Non-Potable Water Signs

The legal side is straightforward: OSHA regulation 29CFR 1910.141(b)(2)(1) requires clear marking of all non-potable water outlets. But this isn't just regulatory box-ticking - it's about preventing genuine health emergencies that can devastate individuals and organisations alike.

Non-potable water sources can harbour harmful bacteria, chemicals, or contaminants that cause serious illness even from brief exposure. The liability risks alone should motivate proper signage. Insurance claims, WorkCover investigations, and potential prosecution under WHS legislation make non-potable water signs a critical risk management tool, not just a compliance exercise.

Consider the cascading effects of a single incident. One worker becoming seriously ill from consuming contaminated water can trigger extensive medical treatment, lost productivity, regulatory investigation, and potential legal action. The costs quickly escalate beyond the immediate medical expenses to include investigation time, potential fines, increased insurance premiums, and damage to your organisation's reputation.

Think about temporary workers, contractors, or visitors who don't know your site layout. They're the ones most likely to make assumptions about water safety, and proper signage protects them while protecting your organisation from liability. Emergency responders present another high-risk group - during incidents, they may need to access water quickly and won't have time to investigate whether sources are safe for consumption.

Design Essentials for Non-Potable Water Signs

Effective non-potable water signs combine several design elements to maximise their impact and ensure clear communication across diverse audiences. High contrast colours ensure visibility from a distance - black text on bright yellow or white backgrounds consistently performs best in real-world conditions. The universal "no drinking" pictogram should accompany text warnings, typically showing a crossed-out glass or person drinking.

Minimum lettering height varies by application, but 20mm works for most industrial uses. In high-risk areas like schools or public spaces, larger text improves readability for people of all ages. Stick to bold fonts like Arial or Helvetica rather than decorative typefaces that sacrifice readability for style.

The key is making your message unmistakable at first glance. Someone approaching a tap or outlet should immediately understand the water isn't safe for drinking, washing, or food preparation. This immediate recognition becomes critical during emergencies or high-stress situations when people might not take time to read detailed warnings.

Consider the viewing environment when selecting colours and contrast levels. Signs in dimly lit plant rooms need higher contrast than those in bright outdoor locations. Reflective materials can improve visibility in low-light conditions, while anti-glare coatings prevent washout in bright sunlight.

Agriculture & Irrigation Sites

Agricultural properties create some of the most challenging environments for non-potable water signs placement. When you're managing irrigation systems that stretch across hectares, with seasonal workers who might not know your property layout, clear signage becomes absolutely critical for safety and regulatory compliance.

The unique challenge here is scale combined with workforce diversity. Unlike a construction site with defined boundaries and regular staff, farms have multiple water sources scattered across vast areas accessed by seasonal workers, contractors, livestock handlers, and emergency services personnel. Your bore water might be perfectly fine for livestock and irrigation, but it's not treated for human consumption. That distinction needs to be crystal clear at every access point.

Seasonal workforce considerations add another layer of complexity. During harvest periods or busy planting seasons, you might have dozens of temporary workers who aren't familiar with your property's water systems. These workers often come from diverse cultural backgrounds and may have varying levels of English proficiency. Your signage strategy needs to account for this reality.

Water storage tanks and headers feeding irrigation lines are your first priority. These central points often have taps or outlets that look identical to drinking water sources. During hot weather, workers naturally gravitate towards any available water source for relief. Position signs prominently on tank sides and near any valve or outlet where someone might fill a water bottle.

Large storage tanks require multiple signs positioned around the perimeter because workers approach from different directions throughout the day. A sign that's perfectly visible from the main farm road might be completely hidden when someone approaches from the machinery shed or livestock yards. We typically recommend at least four signs on tanks larger than 10,000 litres - think of them as compass points ensuring visibility from any approach angle.

Bore pump outlets and wellheads present another high-risk area. These locations typically have robust taps that appear perfectly suitable for drinking. The water quality might vary seasonally or after heavy rains, making consistent signage even more important. Mount signs at eye level and ensure they're visible from multiple approach angles.

Bore water quality can fluctuate significantly based on seasonal conditions, recent rainfall, and surrounding land use activities. What might be relatively safe water during dry periods could become contaminated after heavy rains wash agricultural chemicals or animal waste into groundwater systems. Consistent signage eliminates any guesswork about water safety.

Spray line connection points and valve boxes throughout your irrigation system need attention too. Maintenance work often requires connecting hoses or accessing water directly from these points. Workers focused on repairs might not pause to consider water quality unless clear warnings are present.

These connection points are particularly risky because they're often accessed during equipment breakdowns or urgent repairs when workers are focused on solving problems quickly. The combination of time pressure and readily available water creates natural temptation to drink from convenient sources without considering safety.

The harsh Australian outdoor environment demands serious consideration of materials and mounting methods. Standard vinyl signs that work fine indoors will fade, crack, and become illegible within months under our intense UV exposure. Choose materials specifically engineered for extended outdoor use, with UV inhibitors that maintain both colour and structural integrity for years rather than months.

Wind loading becomes a significant factor in open agricultural environments. Signs need secure mounting that won't create projectiles during severe weather events. Breakaway mounting systems work well in areas where large machinery operates regularly - they prevent expensive equipment damage while ensuring signs can be quickly restored after impact.

High-Risk Spots for Non-Potable Water Signs on Farms

Pivot sprinkler systems deserve special attention because they're frequently accessed for maintenance and adjustments. The pivot point itself needs prominent signage, but don't stop there. Workers often connect temporary hoses or access water at various points along the system's radius. Consider placing additional signs at regular intervals where the system crosses roads or fence lines.

Pivot systems present unique challenges because they're constantly moving, creating different access points throughout their rotation cycle. Workers might encounter connection points or maintenance access areas at various locations depending on the system's position. Strategic signage placement ensures warnings are visible regardless of the pivot's current location.

Fence line entries where irrigation pipes cross property boundaries create unexpected risks. Neighbouring farmers, contractors, or emergency services personnel might encounter these connections without context about your water systems. They see a tap or valve and assume it's safe for drinking. Clear signage prevents these assumptions from becoming health incidents.

Property boundary areas are particularly challenging because they're often accessed by people unfamiliar with your specific water systems. Emergency responders, neighbouring property owners, or contractors working on boundary infrastructure might encounter these water sources during their activities. Clear, prominent signage protects these individuals while protecting your organisation from liability.

Header tanks and pump stations require signage visible from multiple angles. These installations often feature robust taps that look identical to drinking water outlets. The liftd position of many header tanks means signs need to be sized appropriately for ground-level visibility. Don't rely on a single small sign - use multiple markers to ensure visibility regardless of approach direction.

Liftd installations create unique visibility challenges. Signs that are perfectly readable at ground level might be too small to read clearly when mounted on liftd tanks. Consider larger format signs or multiple smaller signs positioned at different heights to ensure effective communication.

Drip irrigation manifolds and control stations might seem less risky, but maintenance crews regularly work around these areas. The combination of physical exertion and readily available water creates natural temptation to drink from convenient sources. Position signs where they'll be noticed before someone reaches for a quick drink.

These areas often involve concentrated maintenance activities where workers spend extended periods adjusting, repairing, or monitoring equipment. The proximity to water sources combined with physical exertion in hot conditions creates high-risk scenarios for accidental consumption.

Maintaining Your Non-Potable Water Signs in the Field

Rural environments test signage durability in ways that urban installations never experience. Mud splash from machinery, particularly during wet seasons, can obscure signs completely. UV exposure at intensity levels that would surprise city dwellers gradually breaks down even quality materials. Potential impact damage from equipment, livestock, or maintenance activities requires robust mounting solutions.

Seasonal challenges vary significantly across different agricultural regions. Northern Queensland properties face intense UV exposure and tropical weather extremes, while southern properties deal with frost, hail, and temperature fluctuations that can crack inferior materials. Coastal agricultural areas add salt spray corrosion to the list of environmental challenges.

Establishing a monthly inspection routine isn't just good practice - it's essential for maintaining effective warnings. Check for fading that reduces contrast and readability. Look for physical damage from weather, animals, or equipment. Watch for vegetation growth that might obstruct visibility as seasons change.

Seasonal vegetation growth can quickly obscure even well-positioned signs. What's clearly visible during winter months might be completely hidden by spring growth. Regular trimming around sign locations should be incorporated into routine property maintenance activities.

Replace signs showing significant wear before they become illegible rather than waiting for complete failure. A faded sign that's difficult to read provides false security while offering little actual protection. Consider mounting signs on breakaway posts in areas where large machinery operates regularly - this prevents expensive equipment damage while ensuring signs can be quickly restored.

The investment in quality materials and regular maintenance pays dividends in sustained safety performance. A sign that remains clearly visible and legible for years costs less per month than cheap alternatives requiring frequent replacement. Factor signage maintenance into your overall property management budget to ensure consistent safety protection.

More information about our agricultural signage services covers specific material options designed for the demanding conditions found across Australian farming operations.

Construction & Civil Worksites

Construction sites are like moving puzzles where non-potable water signs need to keep up with constantly changing layouts and temporary installations. Unlike permanent facilities, construction environments require signage that's both highly visible and flexible enough to relocate as work progresses.

The challenge here is that what's safe drinking water today might be connected to a non-potable source tomorrow. Dust suppression tanks, concrete mixing stations, and equipment washdown areas all use water that's perfectly fine for construction purposes but could make someone seriously ill if consumed.

Portable water tanks used for dust suppression or concrete mixing are prime candidates for multiple signs positioned around the tank perimeter. Workers approach these tanks from different angles throughout the day, and a sign that's perfectly visible from the east side might be completely hidden when you're approaching from the west. We typically recommend at least four signs on large tanks - think of them as the cardinal points on a compass.

Temporary hoses and connections present their own challenges. These move frequently as work progresses, but they still need clear identification. Site welfare facilities can be particularly tricky when potable and non-potable lines run close together. One wrong connection during a rushed repair could contaminate the entire drinking water system.

Equipment washdown areas using recycled or bore water need prominent signage because workers often assume any tap on site provides safe washing water. During hot Australian summers, the temptation to splash some water on your face or rinse your hands is strong - but bore water or recycled wash water isn't suitable for personal use.

The temporary nature of construction work means your signage strategy needs to be just as adaptable as your site layout. Removable tags and pipe markers that can move with equipment save time and ensure compliance as work progresses.

Non-Potable Water Signs for Portable Tanks and Hoses

Mobile water tanks are the workhorses of construction sites, but they're also where most non-potable water incidents occur. The key is making sure every possible approach angle has clear signage. We've seen too many cases where someone filled a drink bottle from the "back" of a tank where no sign was visible.

Hose connections need point-of-use marking that doesn't interfere with daily operations. Small valve tags or wrap-around pipe markers work brilliantly here - they're visible enough to catch attention but won't get in the way when someone's trying to make a quick connection. Position these close enough to the outlet that they're impossible to miss before turning on the tap.

Quick-release mounting systems are game-changers for sites where equipment moves frequently. Magnetic mounts work perfectly on steel tanks, while clip-on systems suit various pipe materials without requiring permanent installation. This flexibility means your safety signage can keep up with the pace of construction work.

Preventing Cross-Connection With Non-Potable Water Signs

Dual plumbing systems in site offices or amenities buildings create some of the highest risk scenarios we encounter. When potable and non-potable lines run close together, clear signage becomes the last line of defence against dangerous cross-connections.

Trade induction should always include identification of non-potable water systems and signage. Many incidents happen when contractors unfamiliar with site-specific systems make assumptions about water sources. A plumber working on a weekend repair might not realise that the unmarked line they're connecting carries bore water, not mains supply.

The consequences of cross-connection go far beyond individual illness - contaminating a site's drinking water supply can shut down operations and trigger serious regulatory investigations. External research on warning signs provides additional guidance for preventing these costly and dangerous mistakes.

Regular toolbox talks should reinforce the importance of checking signage before making any water connections. When work is progressing quickly and deadlines are tight, it's easy to skip what seems like an obvious step - but that's exactly when accidents happen.

Commercial & Industrial Plumbing Networks

Commercial and industrial facilities operate with some of the most complex water systems you'll encounter. These buildings often juggle multiple water sources - potable drinking water, process water for manufacturing, cooling tower circulation, and recycled systems for landscape irrigation. Getting your non-potable water signs placement right in these environments isn't just about compliance; it's about preventing serious incidents when maintenance crews are working under pressure.

Plant rooms present the highest risk areas because they're where multiple water services converge. I've seen facilities with six different water systems running through a single mechanical room, and without clear identification, even experienced technicians can make dangerous assumptions. Your non-potable water signs need to be positioned at every access point - that means cooling tower supply and return lines, process water outlets in manufacturing areas, and any reclaimed water systems feeding irrigation networks.

Emergency shower and eyewash stations create a particular challenge. While these safety systems may use non-potable water for emergency flushing, workers need to understand the water isn't suitable for drinking. The last thing you want during an emergency response is someone developing secondary health issues from consuming contaminated rinse water.

Manufacturing areas require strategic sign placement around process water outlets. These taps might look identical to drinking water sources, but they're often connected to recycled systems or industrial water supplies. Position signs directly adjacent to outlets where they're impossible to miss, even during rushed operations or shift changes.

Audit Checklist: Non-Potable Water Signs Around Process Equipment

Storage tanks demand comprehensive marking because they typically have multiple connection points that could confuse maintenance staff. Your signs need to cover access points, fill connections, and any sampling or drain valves. Industrial tanks often sit in areas where emergency responders or contractors might encounter them during incidents, and these personnel won't know your system layout.

Valve identification becomes absolutely critical in complex industrial systems. We recommend combining colour-coded valve tags with prominent non-potable water signs to create redundant safety measures. This approach proves invaluable during emergency shutdowns when quick identification prevents costly mistakes and potential health hazards.

Emergency shower and eyewash stations present unique signage requirements. While these systems must deliver immediate flushing capability, users need clear warnings if the water isn't potable. Position signs where they're visible during use but won't interfere with emergency access. The signage should indicate the water's purpose while warning against consumption.

Bilingual & Braille Non-Potable Water Signs

Industrial workforces increasingly require multilingual communication, particularly English-Spanish combinations in manufacturing settings. Bilingual non-potable water signs aren't just helpful - they're essential for preventing incidents in diverse workplaces. Pictograms provide universal communication that transcends language barriers entirely, making them particularly valuable in facilities with rotating contractor crews.

Accessibility requirements in commercial facilities may mandate tactile signage options. Braille and raised character signs ensure compliance with disability access standards while expanding safety protection to visually impaired workers and visitors. These specialised signs work best when positioned at consistent heights throughout your facility.

Some commercial buildings require discreet signage solutions that maintain aesthetic standards while meeting safety requirements. Consider smaller format signs with clean typography that blend with architectural finishes while remaining clearly visible to maintenance staff and building users.

Latest research on reclaimed water signage demonstrates how combined text and symbol approaches improve recognition rates across diverse user groups, making this approach particularly valuable in commercial environments with varied occupancy.

Public Spaces, Parks & Community Facilities

Public environments require non-potable water signs that communicate effectively with diverse audiences including children, elderly visitors, and people from various cultural backgrounds. The signage must be vandal-resistant while remaining clearly visible and informative.

Critical placement areas:

- BBQ and picnic area taps not connected to drinking water

- Irrigation system outlets and sprinkler connections

- Decorative water features using recycled water

- Public toilet facilities with dual water systems

- Sports ground irrigation and maintenance areas

Vandal-resistant materials become essential in public spaces. Aluminium or thick plastic signs with tamper-proof mounting hardware prevent removal or damage. Consider anti-graffiti coatings in high-risk areas.

Schools & Childcare: Extra-Safe Non-Potable Water Sign Placement

Educational facilities require special attention because children may not understand text-based warnings. Pictogram-heavy designs with bright colours and simple symbols work more effectively than text-heavy approaches.

Child-height mounting ensures signs are visible to primary users. Standard adult eye-level placement might be too high for children to notice. Mount duplicate signs at both adult and child levels in high-risk areas.

Monthly inspection schedules should include sign condition checks. Children's natural curiosity and play behaviour can damage or obscure signage more quickly than in adult-only environments.

More information about Australian safety sign standards covers specific requirements for educational facilities.

Transport & Logistics Hubs

Vehicle washdown bays commonly use recycled or bore water for cost efficiency. Clear signage prevents drivers or maintenance staff from mistaking these sources for drinking water during long shifts.

Sanitation system refill points need prominent marking. Mobile toilet servicing, greywater disposal, and similar operations use non-potable water that could be confused with potable sources.

Multilingual signage considerations increase in transport hubs with international drivers or diverse workforces. Consider pictogram-heavy designs that transcend language barriers.

Final Checklist Before You Order or Install

You've mapped out your facility and identified the risks - now it's time to make sure nothing slips through the cracks. This final review process has saved countless facilities from expensive oversights and potential liability issues that could have been easily prevented with thorough planning.

Start with complete coverage verification. Walk through your entire site and tick off every non-potable outlet against your signage plan. We've seen too many incidents where obvious sources like main tanks were marked, but smaller maintenance taps or emergency connections were forgotten. Those overlooked outlets often cause the most problems because people assume unmarked water is safe to drink.

Create a comprehensive site map marking every water source, regardless of how minor it might seem. Include seasonal connections, emergency outlets, and maintenance access points that might only be used occasionally. These forgotten sources often present the highest risk because they're encountered by people unfamiliar with your water systems.

Check your viewing angles carefully. Storage tanks need signs visible from multiple approaches because workers arrive from different directions. A sign that's perfectly clear from the main walkway might be completely hidden when someone approaches from the loading dock or maintenance access. Walk each approach route yourself to verify sign visibility from realistic user perspectives.

Consider different times of day and lighting conditions when evaluating visibility. A sign that's clearly visible in bright daylight might be impossible to read during early morning or late afternoon shifts. Factor in seasonal changes that might affect visibility, such as vegetation growth or changing sun angles.

Consider your specific environment when selecting materials. Coastal locations need corrosion-resistant options, while inland agricultural sites prioritise UV stability. Construction sites require impact-resistant mounting that won't damage equipment or create projectiles in windy conditions. Public spaces demand vandal-resistant designs that can't be easily removed or defaced.

Environmental factors extend beyond obvious weather considerations. Industrial environments might involve chemical exposure that degrades standard materials. High-traffic areas need materials that maintain appearance despite frequent handling or accidental contact. Consider the full lifecycle of your signage when making material selections.

Don't forget the purple plumbing identification. AS 2700 requires purple marking on all non-potable fixtures and piping. This colour coding works hand-in-hand with your non-potable water signs to create multiple safety layers. When both elements are properly implemented, the risk of confusion drops dramatically.

The purple identification system should extend throughout your entire non-potable water network, from main supply lines to individual outlets. This creates a comprehensive visual system that reinforces your signage warnings and helps maintenance crews quickly identify system components.

Plan your maintenance approach before installation. Establish who's responsible for regular inspections, how often they'll occur, and what triggers sign replacement. Keep spare signs in stock because weather damage or accidental impact can compromise visibility quickly. Update your signage whenever plumbing systems change - new connections or relocated equipment often create new risk points.

Document your signage locations and inspection schedules to ensure consistent maintenance over time. Staff changes, organisational restructuring, or budget pressures can disrupt maintenance routines unless they're properly documented and assigned to specific roles.

Verify compliance with local requirements. While national standards provide the foundation, some councils or state authorities have additional requirements for specific applications. Public facilities often have stricter accessibility standards, while industrial sites might need additional bilingual signage for diverse workforces.

Local requirements can vary significantly between jurisdictions and may change over time. Stay informed about regulatory updates that might affect your signage requirements. Professional signage providers can help steer these complex requirements and ensure ongoing compliance.

Consider future expansion and modifications. Your current signage plan should accommodate likely future changes to your water systems. New construction, equipment upgrades, or operational changes might create additional non-potable water sources that need immediate identification. Planning for these scenarios prevents gaps in safety coverage.

The investment in comprehensive non-potable water signs pays for itself through avoided liability, improved safety culture, and regulatory compliance. Take the time to get the placement right from the start - it's much more cost-effective than retrofitting after an incident or inspection failure.

Establish clear procedures for updating signage when systems change. New installations, modifications, or equipment relocations should automatically trigger signage review to ensure continued safety coverage. This proactive approach prevents dangerous gaps that could lead to incidents.

Frequently Asked Questions about Non-Potable Water Signs

What is the difference between potable and non-potable water signs?

The distinction between these two types of signs comes down to their purpose and visual design. Potable water signs reassure people that the water is safe for drinking, cooking, and washing. They typically use calming green colours with positive messaging like "Safe Drinking Water" or simply "Potable Water."

Non-potable water signs serve the opposite function - they're warning signs designed to prevent accidental consumption. These signs use attention-grabbing warning colours like bright yellow, orange, or red, paired with clear prohibition messages such as "Do Not Drink," "Non-Potable Water," or "Unsafe for Consumption."

The visual contrast is intentional. While potable signs provide peace of mind, non-potable water signs create an immediate sense of caution. Both types are essential in facilities with multiple water sources, helping people quickly identify which taps are safe for drinking and which aren't.

Are bilingual non-potable water signs mandatory in Australia?

Bilingual signage isn't a legal requirement under Australian standards, but it's becoming increasingly important for workplace safety. If your workforce includes team members who aren't confident English speakers, bilingual non-potable water signs can be crucial for preventing accidents.

WHS legislation requires that safety information is communicated effectively to all workers. This means if you have Spanish-speaking employees, Vietnamese workers, or team members from other language backgrounds, providing signs in their native language alongside English helps you meet your duty of care obligations.

English-Spanish combinations are particularly common in construction and agricultural settings. However, pictogram-heavy designs often work just as well as bilingual text. A clear "no drinking" symbol with a crossed-out glass is universally understood, regardless of language barriers.

The liability perspective also matters here. If someone becomes ill after consuming non-potable water because they couldn't understand your English-only signage, it could complicate insurance claims and WorkCover investigations.

Do pipes and valves need separate non-potable water tags?

Absolutely. While outlet signage catches people before they use a tap, pipe and valve identification protects maintenance workers who interact with your water systems behind the scenes. This dual approach prevents dangerous cross-connections during repairs, installations, or system modifications.

AS 2700 requires purple colour coding for all non-potable water pipes, but additional tags provide crucial point-of-work identification. When a plumber is working in a cramped plant room or underground utility space, clear valve tags and pipe markers prevent potentially serious mistakes.

Wrap-around pipe markers work well for straight runs of piping, while durable valve tags attach directly to shut-off points. These complement your non-potable water signs at outlets by creating a complete identification system throughout your facility.

The redundancy is intentional - different people interact with your water systems in different ways. Visitors and workers see outlet signs, while maintenance crews rely on pipe markers and valve tags. Both groups need clear, unmistakable warnings to stay safe.

Conclusion

Proper placement of non-potable water signs isn't just about ticking compliance boxes - it's about creating safer environments where everyone understands exactly what water they can and can't use. From the sprawling irrigation networks on Australian farms to the complex plumbing systems in city office towers, each site presents its own unique challenges and opportunities for effective signage.

The fundamentals remain consistent across every industry: position signs where they're immediately visible before someone accesses the water, choose materials that can handle your specific environment, and communicate clearly through the right combination of text and symbols. Whether you're dealing with seasonal farmhands who might not speak English as their first language, or maintenance crews working in dimly lit plant rooms, your signage needs to speak to its audience effectively.

What we've learned through years of working with Australian businesses is that the best signage strategies take a site-by-site approach. A construction supervisor managing dust suppression tanks faces completely different challenges than a school facilities manager ensuring children's safety around garden taps. The regulatory requirements might be the same, but the practical implementation needs to fit the real-world conditions of each environment.

Regular maintenance and inspection keep your non-potable water signs working effectively over time. Australian conditions are tough on outdoor signage - our UV exposure, temperature swings, and seasonal weather can quickly degrade poorly chosen materials. That's why investing in quality signage from the start actually saves money in the long run.

At Pinnacle Signage, we've helped thousands of Australian businesses solve their non-potable water signage challenges. We understand the difference between what works in a Brisbane construction site versus a Melbourne commercial building, or a Tasmanian farm versus a Perth industrial facility. Our team knows which materials stand up to local conditions and which designs communicate most effectively in different environments.

Every site is different, which is why we offer customisable solutions rather than one-size-fits-all approaches. Whether you need basic warning labels for a small office building or a comprehensive signage system for a large industrial complex, we can help you identify the right products and placement strategies for your specific situation.

Explore our complete range of non-potable water signage products to find solutions that fit your site's unique requirements. Our experienced team is always ready to discuss your specific challenges and recommend the most effective signage approach for your industry and environment.