An Essential Guide to High Voltage Labels

Why High Voltage Labels Are Critical for Australian Workplaces

A high voltage label is a safety warning sign that alerts workers to dangerous electrical voltage levels that could cause serious injury or death. These labels are mandatory safety devices designed to prevent electrocution accidents by clearly identifying hazardous electrical equipment and systems.

Key Facts About High Voltage Labels:

- Required by law under Australian WHS regulations for electrical equipment

- Voltage thresholds: Generally required for systems over 50V AC or 30V DC

- Standard symbols: Lightning bolt in triangle with red "DANGER" or orange "WARNING" text

- Placement: Must be visible on electrical panels, transformers, switchboards, and high-voltage equipment

- Materials: Durable vinyl or polyester designed to withstand harsh Australian conditions

- Compliance: Must meet AS/NZS standards and Safe Work Australia guidelines

The statistics are sobering - research shows that more than a thousand people are killed and several thousand injured each year in the United States because of electrical current, with most shock deaths resulting from contacts with electrical systems ranging from 70 to 500 volts. In Australia, electrical incidents remain a significant workplace hazard, making proper labelling essential for compliance and safety.

High voltage labels serve multiple critical functions beyond basic warning signs. They communicate specific voltage levels to help workers select appropriate personal protective equipment, provide lockout/tagout instructions, and meet legal documentation requirements under Work Health and Safety legislation.

The consequences of inadequate labelling are severe - from workplace injuries and fatalities to significant legal liability and regulatory penalties. OSHA standards recommend placing high voltage labels on any location with voltage over 600 volts, though Australian standards often require labelling at much lower thresholds.

I'm Doug Lindqvist, and through my years in the safety and industrial supply space, I've seen how proper high voltage label implementation can prevent serious workplace accidents and ensure regulatory compliance. At Pinnacle Signage, we specialise in creating durable, compliant high voltage labels that meet Australian standards and withstand our harsh environmental conditions.

What is a High Voltage Label?

Think of a high voltage label as your workplace's silent guardian - a standardised safety warning that immediately communicates dangerous electrical voltage levels to anyone who approaches. These aren't just stickers; they're carefully designed safety devices that serve as your first line of defence against electrical accidents.

The purpose goes far deeper than a simple "stay away" message. These labels are engineered to prevent electrocution by ensuring everyone - from your regular maintenance crew to visiting contractors - instantly understands the risks they're facing. They're also essential for proper energy isolation procedures, helping workers follow the right lockout/tagout protocols. Most importantly, they help you meet your legal duty of care under Australian workplace safety legislation.

When someone sees that distinctive lightning bolt symbol, they know immediately that special precautions are required. It's this instant recognition that can mean the difference between a safe workday and a tragic accident.

Why every site needs a high voltage label

The statistics tell a sobering story that every Australian business owner needs to understand. Research shows that all electrical systems of 30 volts or more pose potential shock hazards, with most fatal electrocutions occurring from contact with systems between 70 and 500 volts. This means even what might seem like "low voltage" equipment can be lethal under the right circumstances.

From a practical risk reduction standpoint, high voltage labels eliminate dangerous guesswork. They prevent that split-second confusion that can lead to tragedy, especially in environments where multiple voltage levels exist throughout the facility. Your workers can quickly identify which areas require special personal protective equipment and which procedures to follow.

The liability implications are equally serious and often overlooked. Failing to properly label high voltage equipment can result in prosecution under Work Health and Safety legislation, substantial fines that can cripple a business, and devastating civil liability if an accident occurs. We've witnessed cases where inadequate labelling contributed to workplace fatalities, leading to both criminal charges and compensation claims that reached into the millions.

Beyond the legal requirements, proper labelling demonstrates your commitment to worker safety - something that's increasingly important for winning contracts and maintaining your reputation in the industry.

Voltage thresholds that trigger a high voltage label

Understanding when you need a high voltage label can be trickier than it first appears, as different standards apply different thresholds depending on the specific application and industry. However, there are some key benchmarks that guide Australian practice.

The most widely recognised thresholds are 30V DC and 50V AC - these align with voltage levels where electrical shock becomes potentially dangerous to human health. But the picture gets more complex when you look at specific standards.

IEC 61010 takes a more nuanced approach, defining hazardous live conditions as 70V DC at 2mA or more, or 33V AC at 0.5mA or more. MIL-STD-1472H is more conservative, considering any system of 30V or more a potential shock hazard that requires warning labels. Some international standards like OSHA recommend labelling for voltages over 600V, though most Australian safety professionals consider this threshold too high for comprehensive workplace protection.

In Australian practice, we typically recommend labelling any equipment or system operating above 50V AC or 30V DC. This conservative approach ensures maximum safety and keeps you well within regulatory compliance requirements.

There's another factor many people overlook - stored energy. Capacitors and other energy storage devices may require labelling even at lower voltages if they store more than 10 millijoules of energy, as specified in IEC 61010 safety requirements. This is particularly relevant for electronic equipment and power supplies that might seem harmless but can deliver dangerous discharge currents.

Standards and Regulations in Australia and Beyond

The regulatory landscape for high voltage labels in Australia is primarily governed by the AS/NZS 3000 Wiring Rules and the Work Health and Safety Act. These standards work together to establish clear requirements for electrical safety signage and labelling.

Under the WHS Act, employers have a duty to ensure the health and safety of workers, which includes providing adequate warnings about electrical hazards. Safe Work Australia provides guidance on electrical safety, emphasising the importance of proper labelling and signage to prevent electrical incidents.

Internationally, several standards influence Australian practice. OSHA 1910.145 provides comprehensive guidance on accident prevention signs and tags, while ANSI Z535 series standards cover safety sign design and performance requirements.

The IEC 60417 standard provides internationally recognised symbols for electrical equipment, including the lightning bolt symbol commonly used on high voltage labels. Military applications often reference MIL-HDBK-454C, which mandates permanent markings for hazards internal to electronic units.

Global symbols versus Australian practice

While Australia generally follows international standards for electrical safety symbols, there are some important distinctions in local practice. The ISO 7010 standard provides globally recognised safety symbols, including the lightning bolt in triangle that's universally accepted for electrical hazards.

The colour coding system follows international norms but with some local variations:

- Red indicates immediate danger (DANGER labels)

- Orange indicates warning of potential hazard (WARNING labels)

- Yellow indicates caution for non-life-threatening hazards

Australian practice tends to favour the red "DANGER" designation for high voltage applications, particularly those above 1000V, while orange "WARNING" labels are used for lower voltage hazards that still pose significant risk.

Documentation and record-keeping obligations

Proper documentation extends beyond simply applying labels. Australian workplaces must maintain comprehensive records of electrical safety measures, including:

- Risk assessments that identify all electrical hazards and required labelling

- Lock-out/tag-out procedures that reference high voltage labels as part of isolation procedures

- Regular inspection schedules to ensure labels remain legible and properly positioned

- Training records showing workers understand the meaning and implications of different label types

These documentation requirements help demonstrate due diligence in the event of an incident and ensure ongoing compliance with safety regulations.

Designing an Effective High Voltage Label

Creating an effective high voltage label requires careful attention to layout, messaging, and visual design elements. The most successful labels combine clear signal words, appropriate symbols, high colour contrast, and durable construction to ensure maximum visibility and longevity.

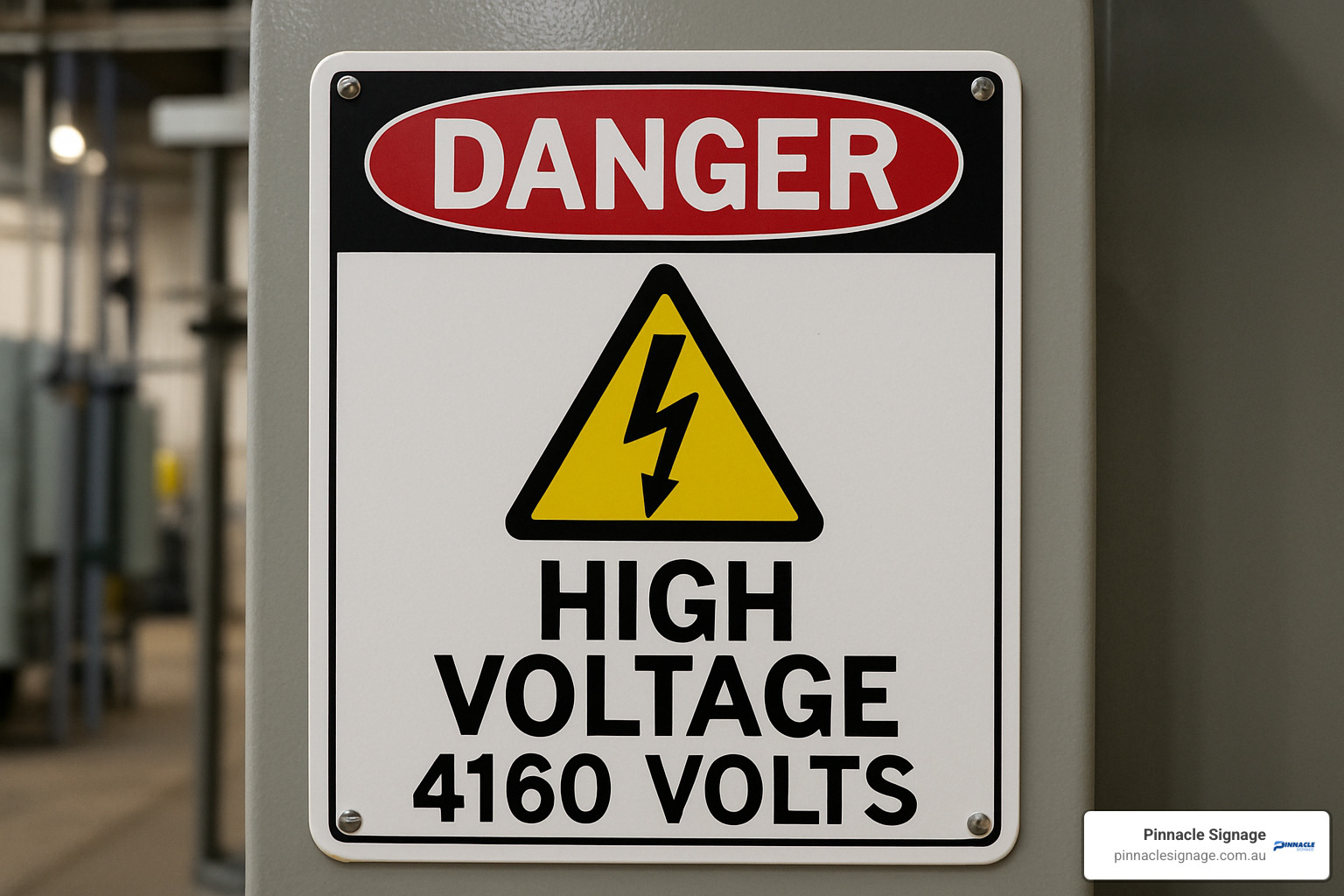

The layout should follow a hierarchical approach, with the signal word (DANGER or WARNING) prominently displayed at the top, followed by the hazard symbol, specific voltage information, and any required instructional text. This structure ensures the most critical information is immediately visible, even from a distance.

Signal word selection is crucial - "DANGER" indicates immediate hazard that will result in death or serious injury, while "WARNING" indicates potential hazard that could result in death or serious injury. For high voltage applications, "DANGER" is typically appropriate for systems above 1000V, while "WARNING" may be suitable for lower voltages that still pose significant risk.

Symbol size must be proportional to viewing distance and label size. The lightning bolt symbol should be large enough to be clearly visible from the maximum expected viewing distance, typically at least 25mm in height for close-up applications and proportionally larger for distant viewing.

Colour contrast is essential for visibility in various lighting conditions. High contrast combinations like black text on yellow background or white text on red background provide maximum legibility. We always test our colour combinations under different lighting conditions to ensure they remain visible in typical workplace environments.

Standard symbols and colour schemes for a high voltage label

The lightning bolt in triangle symbol is universally recognised for electrical hazards and should be the primary symbol on any high voltage label. This symbol is defined in IEC 60417 and ISO 7010 standards and is immediately recognisable across different cultures and languages.

Colour schemes follow established safety conventions:

- Danger Red: Used for immediate hazards, typically voltages above 1000V

- Warning Orange: Used for significant hazards, typically voltages from 50V to 1000V

- Caution Yellow: Used for lower-level hazards that still require attention

Some applications may benefit from additional visual elements like QR codes or barcodes that link to detailed safety procedures or equipment information, though these should supplement rather than replace standard warning elements.

Mandatory text and voltage ratings

Every high voltage label must include specific text elements to be fully compliant and effective. The exact voltage should always be specified - generic "HIGH VOLTAGE" warnings are less effective than specific voltage ratings like "415V" or "11kV".

Essential text elements include:

- Specific voltage rating (e.g., "415V AC" or "48V DC")

- "Turn off power before servicing" or similar lockout instruction

- Contact information for emergency situations (where appropriate)

For multicultural workplaces, bilingual labels in English and the predominant second language can significantly improve safety outcomes. We've seen particular success with English/Chinese and English/Arabic combinations in certain industries.

The text must be large enough to read from the expected viewing distance and should use clear, simple language that's easily understood by workers with varying levels of English proficiency.

Materials and adhesives for every environment

Australian conditions demand robust materials that can withstand extreme temperatures, UV exposure, moisture, and physical abuse. We typically recommend:

Vinyl labels with acrylic adhesive for indoor applications and moderate outdoor use. These offer good durability and cost-effectiveness for most applications, with expected lifespans of 3-5 years outdoors.

Polyester labels with aggressive adhesives for harsh environments. These materials resist chemicals, water, and temperature extremes better than vinyl, making them ideal for industrial applications.

Reflective materials for low-light conditions or emergency situations. These incorporate engineered glass-bead technology to improve visibility when illuminated by flashlights or emergency lighting.

Hi-tack adhesives are essential for difficult surfaces including textured metals, powder-coated surfaces, and slightly contaminated areas. Ultra-Stick formulations can bond immediately to uneven or dirty surfaces where standard adhesives would fail.

UV-laminate options extend outdoor life significantly, particularly important in Australia's harsh sun conditions. Laminated labels can achieve 7-10 years of outdoor exposure while maintaining legibility.

Placement and Application Best Practices

Proper placement of high voltage labels is as important as their design. Labels must be positioned where they're immediately visible to anyone approaching hazardous equipment, preferably at eye level and directly adjacent to access points.

Installation zones should be clearly defined during the design phase of any electrical installation. We recommend placing labels at every point where someone might access high voltage components, including:

- Main access panels and doors

- Removable covers or guards

- Service points and connection terminals

- Adjacent to isolation switches

Visibility requirements extend beyond simple line-of-sight. Labels must remain visible under normal working conditions, including when other equipment or materials are present. This often means using larger labels or multiple labels to ensure visibility from different approaches.

Surface preparation is crucial for long-term adhesion. Surfaces should be clean, dry, and free from oils, dust, or other contaminants. For powder-coated or textured surfaces, we often recommend light abrasion to improve adhesive contact.

Regular inspection schedules should verify that labels remain legible, properly adhered, and positioned correctly. We recommend quarterly inspections for critical applications and annual inspections for general use.

Equipment & enclosures: where to stick the high voltage label

Switchboards require labels on the main access door and any removable panels. The main label should indicate the highest voltage present, while individual circuit labels may show specific voltages for different sections.

Transformers need labels on all accessible sides, as maintenance may approach from multiple directions. Both primary and secondary voltages should be clearly indicated, along with any special hazards like oil-filled units.

Battery banks present unique challenges as they may have relatively low voltages but extremely high current capabilities. Labels should indicate both voltage and current hazards, along with specific warnings about arc flash potential.

Motor control centres require labels on each compartment door, with specific voltage and current ratings for each section. These installations often have multiple voltage levels present, making clear labelling essential.

PCB high voltage label requirements

Printed circuit board labelling presents unique challenges due to space constraints and the need to maintain electrical clearances. High voltage labels on PCBs must be carefully positioned to avoid interfering with creepage and clearance requirements.

Component density often limits label placement options. We work with designers to identify suitable locations during the PCB design phase, ensuring labels don't interfere with component placement or heat dissipation.

IEC 61010 requires that capacitors discharge to safe voltages within 10 seconds of power removal. This requirement often necessitates specific labelling on PCBs to warn of stored energy hazards even after power is removed.

Silkscreen printing is often the most practical method for PCB labels, though adhesive labels may be used where silkscreen isn't feasible. The key is ensuring the warning remains visible and legible throughout the product's service life.

Maintaining legibility over time

Label degradation is inevitable, but proper maintenance can significantly extend service life. Cleaning schedules should use appropriate solvents that won't damage label materials or adhesives.

Replacement intervals depend on environmental conditions and label materials. Indoor applications may last 10+ years, while harsh outdoor conditions may require replacement every 3-5 years.

Regular photography of label installations can help track degradation and plan replacement schedules. This documentation also provides evidence of ongoing compliance efforts.

Industry-Specific Considerations & Common Pitfalls

Every industry brings its own unique challenges when it comes to high voltage label implementation. What works perfectly in a clean office environment might fail miserably on a dusty construction site or in a sterile medical facility. Understanding these differences can mean the difference between effective safety communication and costly label failures.

Construction cranes operating in remote locations face completely different challenges than medical imaging equipment in climate-controlled hospitals. Defence systems might require specialised colour schemes that don't interfere with camouflage requirements, while EV chargers need labels that remain visible and functional through years of outdoor weather exposure.

The key is matching your labelling approach to your specific operational environment. We've learned this lesson through years of working with clients across diverse industries - what seems like a minor detail during specification can become a major safety issue down the track.

Industrial & construction sites

Construction environments are particularly unforgiving for high voltage labels. Between the constant exposure to dust, rain, UV radiation, and the inevitable knocks from equipment and materials, labels need to be built tough from day one.

Outdoor exposure in Australia's harsh conditions demands UV-resistant materials and aggressive adhesives that can handle temperature swings from freezing winter mornings to scorching summer afternoons. We've found that laminated polyester labels with UV-protective coatings consistently outperform other options in these demanding applications. The extra cost upfront pays for itself when you're not replacing faded or peeling labels every year.

The challenge becomes even more complex when you're dealing with bilingual workforces, which are increasingly common across Australian construction sites. Safety communication breaks down completely if workers can't understand the warnings. English/Chinese, English/Arabic, and English/Spanish combinations are the most frequently requested, though we regularly work with other language pairs depending on the specific workforce composition.

Temporary installations add another layer of complexity. Labels need to be durable enough for long-term use but may need to be removed and repositioned as projects evolve. This requires careful adhesive selection - strong enough to stay put in harsh conditions, but removable when necessary without leaving residue or damaging surfaces.

Medical, mining and military gear

Medical equipment presents a fascinating challenge because high voltage labels must survive sterilisation processes that would destroy standard labels. Steam sterilisation, chemical disinfection, and even radiation sterilisation are all part of routine hospital operations. We work with medical device manufacturers to develop labels using specialised materials and adhesives that maintain their integrity and legibility through these harsh cleaning cycles.

Mining equipment operates in some of the most extreme conditions imaginable. Dust, moisture, chemicals, and constant mechanical abuse are just part of daily operations. Labels in these environments often require protective coatings or recessed mounting to prevent physical damage. We've seen standard labels completely obliterated within weeks in mining applications, which is why we always recommend our most robust material options for these sites.

Military applications bring their own unique requirements, particularly around colour restrictions that might conflict with standard safety colours. Camouflage requirements can't be ignored, but safety can't be compromised either. We work closely with defence contractors to develop solutions that meet both safety standards and operational requirements - sometimes this means using infrared-reflective materials that are invisible to the naked eye but clearly visible through night vision equipment.

Common mistakes to avoid

The most frustrating part of our job is seeing easily preventable mistakes that compromise safety and waste money. Wrong voltage printed on labels is surprisingly common, especially during equipment modifications or upgrades. We always recommend double-checking actual voltages with a qualified electrician before finalising any label order, and updating labels immediately whenever electrical modifications are made.

Labels applied under paint or powder coating render them completely useless - you'd be amazed how often this happens during refurbishment projects. Labels should always be the final step in any finishing process, applied after all coatings have cured and been inspected.

Adhesive failure is usually traced back to poor surface preparation or choosing the wrong adhesive for the application. Oil residue, dust, or moisture on the surface will cause even the best adhesive to fail prematurely. Taking a few extra minutes to properly clean and prepare surfaces before application can extend label life by years.

We also see many installations where labels are simply too small for the viewing distance. A label that's perfectly readable up close becomes useless if workers need to identify hazards from across a room. This is particularly important in electrical switch rooms where maintaining safe distances is critical - the label needs to be readable from the safe approach distance, not just when you're standing right in front of the equipment.

Frequently Asked Questions about High Voltage Labels

Do I need a high voltage label below 600 V?

Absolutely - and this is one of the most common misconceptions we encounter. While some international standards suggest 600V as a threshold, Australian practice is much more conservative and safety-focused. We typically recommend high voltage labels for any system operating above 50V AC or 30V DC.

This lower threshold isn't just regulatory box-ticking - it's based on the sobering reality that electrical shock can be harmful or fatal at much lower voltages than many people realise. The human body's resistance varies dramatically depending on conditions like moisture, cuts, or even just sweaty hands. What might seem like a "safe" 240V household circuit can absolutely be lethal under the wrong circumstances.

The confusion often comes from the electrical industry's technical definition of "high voltage" (typically 1000V and above) versus safety labelling requirements. For safety purposes, we're not worried about technical classifications - we're focused on anything that could hurt someone.

Safe Work Australia's guidance supports this conservative approach, and frankly, the cost of a label versus the potential cost of an accident makes this an easy decision. Better to over-label than under-protect your workers.

Can I create a custom label if standards already exist?

Yes, you can - and often should - create custom labels, provided they meet or exceed the standard requirements. Standards give us the minimum safety baseline, but your specific workplace might need additional information to keep people safe.

We regularly design custom high voltage labels that include standard safety symbols and colours while adding crucial site-specific details. Common customisations include exact voltage ratings (like "415V 3-phase" instead of generic "high voltage"), bilingual text for multicultural workforces, and specific isolation procedures relevant to your equipment.

Some clients add QR codes linking to detailed safety procedures or equipment manuals - brilliant for complex installations where a small label can't contain all the necessary information. Others need company logos for asset management or special materials for harsh environments.

The key principle is that custom elements should improve safety communication, not replace it. Your lightning bolt symbol, danger colours, and clear voltage information must still be there - you're just making the label work harder for your specific situation.

How long should a label last outdoors in Australia?

This is where Australia's harsh conditions really test your label investment. Quality vinyl labels typically give you 3-5 years outdoors, while laminated polyester labels can stretch to 7-10 years if you choose the right materials.

Australia's UV levels are brutal - what might last a decade in European conditions can fade to illegibility in just a couple of years here. We've seen labels in Darwin that looked like they'd been sandblasted after just 18 months, while the same materials in Melbourne performed beautifully for years.

Coastal environments add salt spray to the mix, which accelerates both UV degradation and adhesive failure. Mining sites throw in dust, chemicals, and mechanical abuse. Each environment needs its own approach.

Rather than gambling on maximum lifespan, we recommend building planned replacement schedules into your maintenance program. Quarterly visual inspections for critical equipment, annual reviews for general applications, and immediate replacement for any label that's becoming hard to read.

The cost of a replacement label program is negligible compared to the potential consequences of an illegible warning. Plus, it demonstrates ongoing commitment to safety compliance - something that looks very good if you're ever dealing with regulators or insurance claims.

Conclusion

Getting your high voltage label strategy right isn't just about ticking compliance boxes - it's about creating a safer workplace where everyone goes home safely each day. The small investment in quality labels and proper installation can prevent devastating accidents and save lives.

After years of working with Australian businesses across every industry, I've seen how proper electrical safety labelling makes a real difference. From construction sites in Darwin's tropical heat to mining operations in the Pilbara's harsh conditions, the right high voltage label needs to perform when it matters most.

At Pinnacle Signage, we've built our reputation on understanding exactly what Australian workplaces need. Our labels aren't just designed to meet AS/NZS standards - they're engineered to survive everything our climate can throw at them, from cyclone-strength winds to UV levels that would make other labels fade to nothing.

What sets us apart is our genuine commitment to getting it right the first time. We don't just manufacture labels - we work with you to understand your specific hazards, environmental conditions, and operational requirements. Whether you're dealing with 415V switchboards that need bilingual warnings or medical equipment that requires sterilisation-resistant materials, we've got the experience and materials to deliver.

The peace of mind that comes from knowing your electrical safety labelling is properly specified, expertly manufactured, and correctly installed is invaluable. When workplace safety inspectors visit, when insurance assessors review your risk management, or when new employees start work, you'll have confidence that your high voltage labels are doing their job.

Don't leave electrical safety to chance. Our team understands the unique challenges of Australian conditions and can help you develop a comprehensive labelling solution that protects your people and your business.

Looking for compliant high voltage labels? Explore our full range of high voltage signage here. For custom solutions or expert advice, our team is ready to help you boost electrical safety and meet all regulatory requirements.