All About Machinery Sticker Kits

Why Machinery Sticker Kits Matter for Australian Workplaces

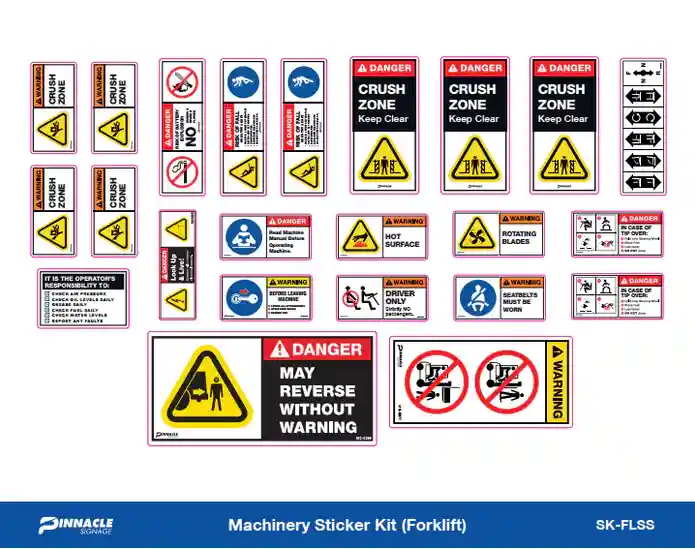

Machinery sticker kits offer a straightforward solution for labelling and safety marking on industrial equipment. Each kit contains the necessary stickers to help ensure a machine is compliant with safety regulations and operational protocols.

What Machinery Sticker Kits Provide:

- Safety compliance: Pre-designed hazard warnings for crush zones, pinch points, electrical risks, and tipping hazards.

- Professional restoration: Brand logos, model numbers, and operational decals to restore equipment appearance.

- Quick installation: Most kits come pre-masked and ready to apply to clean, smooth surfaces.

- Durable materials: Made from quality sign-grade vinyl that's water and fade-proof for long-term use.

Common Kit Types:

- Universal kits for general safety applications.

- Model-specific kits for exact equipment models (e.g., Bobcat, Caterpillar, John Deere).

- Custom kits for unique machinery or specific branding requirements.

Heavy machinery is the backbone of Australian industry, from construction sites to mining operations and farms. Keeping this equipment safe, compliant, and professionally presented is a constant challenge. Faded decals and missing safety labels not only look unprofessional but can create serious safety risks. Machinery sticker kits solve both problems by providing a complete set of safety warnings and branding elements in one package. They play a dual role in enhancing safety and maintaining equipment value, making them essential for any business operating heavy machinery.

The Dual Role of Machinery Stickers: Safety and Branding

Machinery sticker kits are practical tools that directly impact workplace safety and the professional integrity of your machinery. In the demanding Australian environment, where equipment faces harsh sun, dust, and tough working conditions, these stickers serve two critical functions.

Enhancing Workplace Safety with Clear Visual Communication

On any worksite with heavy equipment, machinery safety stickers act as the first line of defence. They provide instant visual warnings to operators and personnel about potential hazards, reinforcing safe operating procedures. On a busy construction site or farm, clear safety communication is vital. Well-designed stickers cut through the noise and deliver critical information at a glance, helping to create a safer environment for everyone.

These visual cues are a practical application of broader workplace safety principles. For more insight, our guide on workplace safety signs explores this topic in detail.

Common hazards addressed by machinery safety stickers include:

- Crush zones: Areas where limbs could be caught between moving parts or the machine and another object.

- Pinch points: Spots where body parts could be caught between components like gears or hinges.

- Electrical risks: Warnings for high-voltage components.

- Tipping hazards: Alerts on equipment like forklifts and skid steers about the risk of overturning.

- Other warnings: Stickers for overhead loads on cranes and reversing vehicle alerts.

Maintaining clear, readable safety stickers is not just good practice; it's often a legal requirement. Safe Work Australia provides comprehensive guidance on managing risks associated with plant and machinery. You can review their resources on managing risks of plants for more information.

Restoring and Branding Your Equipment

Beyond safety, machinery sticker kits are crucial for maintaining your equipment's professional appearance. Heavy machinery is a substantial investment, and keeping it looking sharp reflects well on your business. Over time, original decals fade, peel, or get damaged, making the machine look tired and rendering important information unreadable.

Replacing worn-out decals with a fresh machinery sticker kit can transform an older machine, especially after a repaint. New decals provide the finishing touch that restores the equipment's appearance.

These kits also ensure brand consistency across a fleet. A line of excavators or tractors with uniform, vibrant logos strengthens your company's image, making your operations look organised and professional. For businesses wanting to maintain a strong visual identity, these kits are an invaluable asset.

What's Included in a Typical Machinery Sticker Kit?

A comprehensive machinery sticker kit is a curated package designed to cover essential safety warnings, operational instructions, and branding elements. These kits ensure all critical information is present, visible, and supports workplace safety protocols.

Here's a breakdown of what you'll typically find inside a well-designed kit.

Essential Safety and Warning Labels

The core of any kit is its safety and warning labels, which communicate potential dangers to operators. Understanding the hierarchy of these labels is vital for risk management, a topic covered in our guide on understanding danger labels and safety signage.

- Danger: Reserved for the most severe hazards that could result in death or serious injury, such as "Danger High Voltage" or "Danger Crush Risk." A quality danger sign is non-negotiable for high-risk areas, like this danger chemical storage sign at Bunnings.

- Warning: Used for hazards that could cause serious injury or death if not avoided, like "Warning Hot Surface" or "Warning Rotating Blades."

- Notice: Provides important instructions that are not directly hazard-related but are crucial for proper operation, such as "Notice Read Machine Manual Before Operating."

- Mandatory: Indicates required actions, such as "Mandatory Wear Seatbelt."

These labels use universally recognised symbols and are printed on quality, water and fade-proof vinyl for long-term outdoor use.

Operational, Branding, and Identification Decals

Kits also include decals for operational efficiency, brand identity, and equipment identification.

- Brand logos and model numbers: Restore the machine's original appearance (e.g., Bobcat 731, John Deere) and assist with parts ordering and asset tracking.

- Fluid identification labels: Stickers for "Diesel Fuel" or "Hydraulic Oil" prevent costly maintenance errors. For more on this, see our beginner's guide to adhesive pipe markers.

- Maintenance and safety feature labels: These indicate grease points, service intervals, or the presence of a ROPS (Roll-Over Protective Structure), streamlining maintenance and reinforcing safety.

The combination of these decals makes a machinery sticker kit a comprehensive solution, ensuring all information is clearly and durably displayed.

Types of Kits and Common Machinery Applications

Machinery sticker kits are available in different forms to suit various needs and applications.

Universal vs. Model-Specific Machinery Sticker Kits

There are two main options: universal and model-specific kits.

- Universal kits provide general safety labels applicable to a wide range of machinery. They are a cost-effective solution for diverse fleets or older equipment where specific kits are unavailable. They offer flexibility for supplementing existing decals but may lack model-specific branding or operational stickers.

- Model-specific kits are custom to a particular make and model, such as a Bobcat 731 or MT50. They include all original safety, operational, and branding decals for a factory-finish restoration. This is the ideal choice for restoring a machine to its original appearance and ensuring compliance with manufacturer specifications.

A model-specific kit is generally used for a complete restoration or for common equipment models. A universal kit is often applied for basic safety additions, to supplement missing decals, or for unique machinery.

Sticker Kits for Common Heavy Equipment

Machinery sticker kits are used across every industry that relies on heavy equipment, providing essential safety and operational clarity.

- Agriculture: Tractors, harvesters, and wood chippers require robust signage for PTO shafts, hydraulics, and moving blades to withstand demanding farm environments.

- Construction: Excavators, loaders, and cranes need comprehensive kits covering crush points, electrical risks, and tipping dangers to ensure safety on busy sites.

- Warehousing: Forklifts and material handlers use stickers to warn of overhead loads, crush zones, and reversing vehicles. Our quick start guide to warehouse safety signs offers more on this topic.

- Mining and Road Transport: Heavy-duty machinery in these sectors relies on durable stickers for safety warnings and operational instructions in extreme conditions.

In every industry, clear and durable stickers are crucial for communicating vital information and enhancing safety.

Best Practices for Sticker Application and Maintenance

To get the most out of your machinery sticker kit, proper application and ongoing care are essential. High-quality stickers need correct handling to ensure they improve safety and maintain equipment aesthetics long-term.

Matching Stickers to Machinery and Environment

Before applying a kit, it's important to assess the specific context.

- Risk Assessment: The selection of safety labels is often informed by a site-specific risk assessment for each machine. This process identifies unique hazards and ensures the chosen labels address the actual dangers operators face.

- Machinery Type and Use: Kits are matched to the equipment. Model-specific kits are ideal for an exact OEM appearance on common models like a Bobcat 731, while universal kits are practical for general-purpose machines or for supplementing existing signage.

- Custom vs. Pre-made: While pre-made kits offer convenience and standardised warnings, custom-designed kits are an option for unique machinery, specific branding, or combining safety messages with company logos.

- Operating Environment: The conditions a machine endures will influence the durability required. Exposure to harsh sun, chemicals, or abrasion requires robust materials. Quality sign-grade vinyl is designed to withstand tough Australian conditions, being water and fade-proof.

Application and Long-Term Care

Proper application and maintenance are crucial for sticker longevity and effectiveness.

- Surface Preparation: This is the most critical step. The surface must be clean, dry, and smooth. Remove all dirt, grease, and old adhesive residue for lasting adhesion.

- Application Technique: Most quality kits come pre-masked for easy installation. Peel back a portion of the backing, align the decal, and apply it slowly while smoothing out air bubbles with a squeegee.

- Regular Inspections: Routinely check stickers for fading, peeling, cracking, or physical damage. The Australian sun can be harsh, so make this part of your regular equipment checks.

- Cleaning: Use mild detergents during wash-downs. Avoid abrasive cleaners or high-pressure sprays aimed directly at sticker edges, as this can cause lifting.

- Timely Replacement: An illegible safety warning is a serious risk. Replace worn, faded, or damaged safety stickers promptly to ensure continuous compliance and safety.

Frequently Asked Questions about Machinery Stickers

Here are answers to some common questions about the practical side of using machinery sticker kits.

How long do machinery stickers last?

The lifespan of a sticker depends on the material quality and operating conditions. High-quality machinery sticker kits made from sign-grade vinyl are built for Australian conditions, being water and fade-proof.

With proper application, quality vinyl stickers with UV protection can last 5 to 7 years or more. However, the harsh Australian environment can reduce this lifespan. Factors include:

- UV exposure: Constant, intense sun is the biggest factor in fading.

- Chemicals: Contact with industrial cleaning agents or fuel spills can cause damage.

- Physical abrasion: Scraping and rubbing will wear down the surface.

Regular inspection is key. If a sticker is faded, peeling, or damaged, it should be replaced.

Can I create a custom sticker kit for my specific needs?

Yes. While pre-made kits suit most applications, many businesses have unique requirements. Custom machinery sticker kits are ideal for specialised machinery, specific internal safety protocols, or maintaining a consistent brand identity across a fleet.

A custom kit allows you to combine safety and branding elements seamlessly. You can include warnings for unique hazards, add asset tags, and incorporate your company logo and colours. This creates a solution that works precisely for your operational needs. To get an idea of what's possible, you can explore options like our customised hazchem signage and contact our team to discuss your specific requirements.

Are these stickers easy to apply myself?

Yes, applying machinery sticker kits is generally straightforward. Most quality kits come pre-masked and ready to install, which helps with alignment.

The process involves thorough surface preparation, which is the most critical step. The surface must be clean, dry, and smooth. Once prepared, you align the sticker, apply it using a squeegee to remove air bubbles, and then peel off the transfer tape.

While patience helps, professional installation is not usually required. The key is careful surface preparation; get that right, and the rest of the process is quite simple.

The Value of High-Quality Machinery Decals

Investing in high-quality machinery sticker kits is a practical step towards a safer and more professional worksite. From helping to ensure compliance with Australian safety protocols to maintaining the value and appearance of expensive equipment, these kits play a vital role. By using durable, clearly printed decals, businesses can effectively communicate hazards, streamline operations, and uphold their brand image. Regular inspection and maintenance of these stickers ensures they continue to serve their purpose, protecting personnel and assets in demanding industrial environments.

For quotes, bulk orders, or custom kits, contact our team via the Pinnacle Signage contact page. Prefer retail? Find our products at your local Bunnings or shop the Pinnacle Signage range online.