Mounting Mastery: Your Guide to Installing Signs

Why Proper Sign Installation Matters for Australian Workplaces

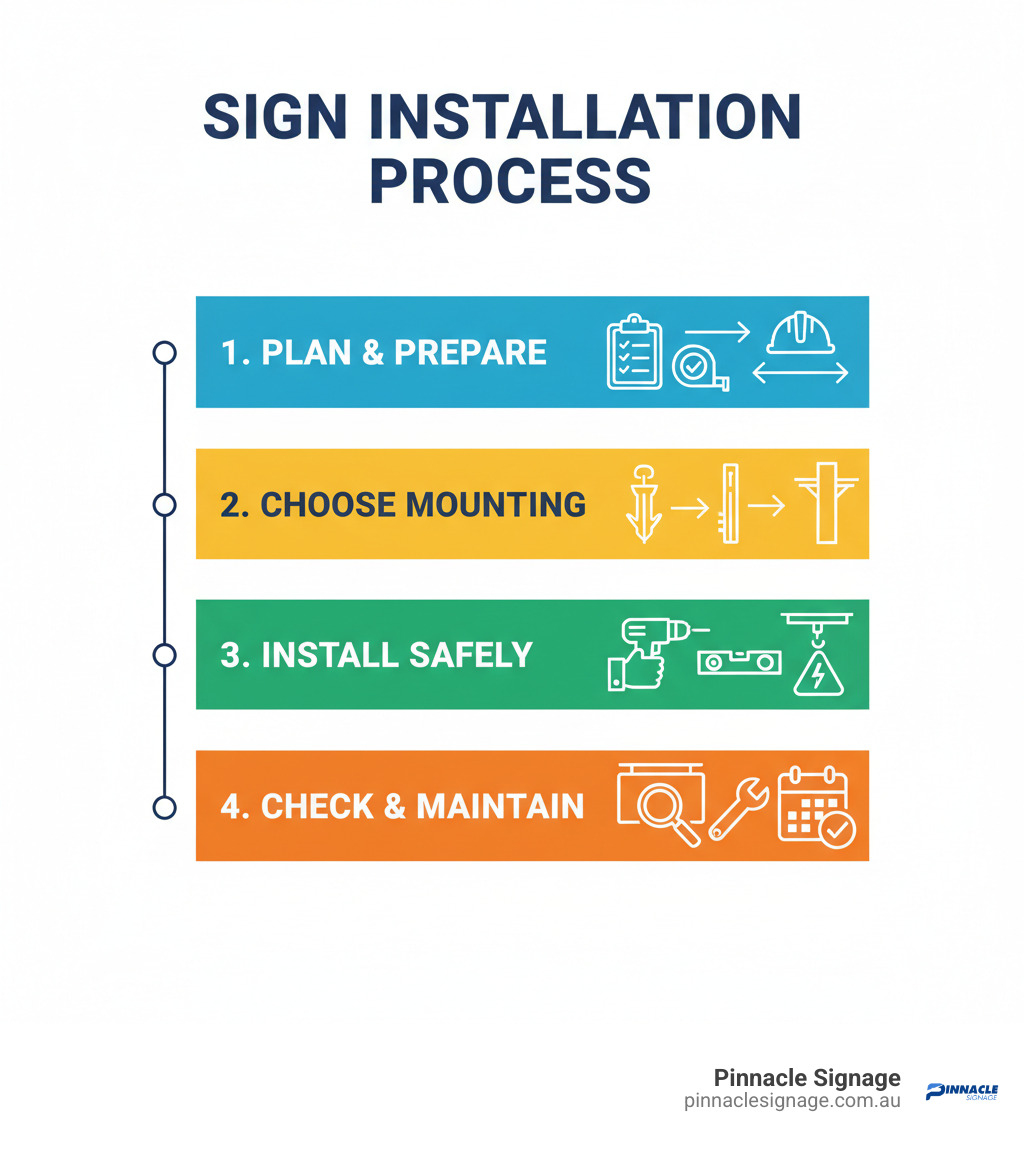

Correct sign installation is essential for workplace safety, communication, and regulatory compliance. The process involves careful planning and preparation, which includes assessing the site, gathering the right tools, and checking local regulations. From there, you'll choose a suitable mounting method, such as wall mounting, post mounting, or ceiling hanging. The installation itself must be done safely, using the correct fixings and ensuring the sign is level and visible. Finally, post-installation checks and a regular maintenance schedule are crucial for long-term stability and effectiveness.

Whether you're marking hazards on a construction site or directing traffic in a car park, the way you install your signs directly impacts their effectiveness. Poor installation can lead to accidents, compliance failures, and frustrated staff or visitors.

This guide covers everything from site assessment and tool selection to specific techniques for wall mounting, post installation, and temporary signage. You'll learn how to choose the right fixings, position signs for maximum visibility, and maintain them for long-term durability. Proper sign installation knowledge is critical for Australian businesses facing tight timelines and strict safety requirements. This guide will help you get it right the first time, whether you're handling the installation yourself or preparing a site for professional installers.

Before You Begin: Planning and Preparation

Proper planning is the difference between a sign that lasts for years and one that fails. It involves understanding your site, gathering the right gear, and ensuring you meet all legal and safety requirements to avoid derailing your project. Taking the time to plan properly saves headaches, money, and potentially dangerous situations. Here’s what you need to know before you start.

Essential Tools and Materials

Having the right toolkit on hand prevents delays and emergency trips to the hardware store.

For measuring and alignment, a tape measure is essential for placement, while a spirit level ensures your sign is perfectly straight. A wonky sign looks unprofessional and is immediately noticeable.

For drilling and fastening, you'll need a drill with bits suitable for wood, masonry, or metal. The right fasteners are just as important. Screws and wall plugs work for brick and concrete, while heavy-duty adhesives may suit certain smooth surfaces. Bolts may be necessary for heavier signs.

Safety gear is non-negotiable. Always wear safety glasses to protect your eyes from debris. Depending on the installation height, you might need ladders, scaffolding, or other access equipment. Never compromise on safety.

Different signs and surfaces require different mounting solutions. We offer a comprehensive range of sign fixings designed for various applications.

Site Assessment and Preparation

A thorough site assessment is key to a successful installation and helps avoid costly mistakes.

Start by examining the mounting surface. A solid brick wall requires a different approach to drywall, timber, or a metal facade. For ground-mounted signs, assess the soil type to ensure it can support the sign's weight.

Look for obstructions, both visible and hidden. Overhead power lines are a serious hazard, as are underground pipes and cables. The "Dial Before You Dig" service is a free and essential tool to prevent catastrophic accidents and expensive damage. Always use it before any ground penetration.

Finally, ensure the surface is prepared. The mounting area must be clean, dry, and free from grease or loose debris. This is especially critical for adhesive-based installations.

Understanding Local Regulations

Ignoring local regulations can lead to fines, forced removal, or legal complications. Compliance is essential.

Local council requirements vary significantly across Australia, with specific rules governing the size, type, placement, and illumination of signs. Regulations often differ for on-property signs (like a storefront sign) and off-property signs (like a billboard).

Permits and zoning laws add another layer of complexity. Larger or illuminated signs often require permits, and zoning laws dictate what types of signs are allowed in commercial, residential, or industrial areas.

Always check with your local council before you start. A quick phone call or visit to their website can save you enormous headaches. For broader guidance on Australian business regulations, business.gov.au is an excellent resource.

Sign Placement Strategy: Maximising Visibility and Impact

A sign's effectiveness depends on strategic placement. It must be in the right place, at the right height, to be seen and understood by its intended audience, whether for safety, navigation, or information.

Understanding Safety and Navigational Signs

Signs are essential communication tools that serve distinct purposes.

Safety signage protects people by warning of hazards, mandating personal protective equipment (PPE), or prohibiting dangerous actions. For instance, our prohibition signage helps prevent unsafe behaviour, while mandatory signage ensures everyone knows what safety measures are required.

Navigational or wayfinding signs guide people through complex spaces like shopping centres or hospitals, reducing confusion and improving visitor experience. In emergencies, they can save lives by directing people to exits. Our guide on access control door signage explores how these signs work.

Informational signs communicate policies, opening hours, or site rules to manage expectations and maintain order.

Proper signage in car parks, from speed limits to pedestrian warnings, can significantly reduce the tens of thousands of accidents that occur in these areas across Australia each year. It’s a clear example of how the right sign in the right place prevents harm.

Determining Optimal Height and Position

The golden rule is simple: place your sign where your audience is looking.

For drivers, signs are most effective between 1.2 and 2.1 metres from the ground. This height optimises visibility from inside a vehicle. When installing signs near roads, also consider a lateral offset of at least 3.6 metres from the edge of the travelled way for safety.

For pedestrians, eye-level placement is best, typically between 1.2 and 1.8 metres high. Position signs where people naturally look as they walk, such as in office buildings or public facilities.

Place signs at key decision points like intersections, building entrances, or lift lobbies, where people are actively looking for guidance.

Accessibility is non-negotiable. Braille signage has specific height requirements (typically 1200mm to 1600mm to the centre of the sign) and must be positioned beside the door it identifies. Our range of Braille and tactile signage meets these standards, ensuring everyone can steer your space safely.

Interior vs. Exterior Placement Considerations

The environment where you install a sign changes your approach.

Exterior signs face the full force of the Australian climate, including intense UV exposure, rain, and wind. They require weather-resistant materials like aluminium and durable fixings. The signs must remain visible and legible despite fading or damage. Our tips for durable, weatherproof signage explain how to make signs last outdoors. When placing exterior signs, also account for natural light to ensure readability throughout the day.

Interior signs have their own considerations, such as indoor lighting, viewing angles, and aesthetic integration. While you might use less robust materials, placement must still be precise. A sign that is perfectly positioned for someone standing directly in front of it might be invisible to someone approaching from an angle.

Outdoor signs prioritise durability, while indoor signs can focus more on appearance. However, both must be visible and effective to achieve their goal: putting the right information in front of people when they need it.

The Ultimate Guide on How to Install Signs

With planning and placement covered, let's look at practical installation methods. The right technique depends on the sign, surface, and desired permanence.

Wall Mounting Techniques

Wall mounting is a common method, but the key is to match the fixing to the wall material.

-

Surface Types:

- Drywall: Use toggle bolts or plastic anchors for light signs. For heavy signs, secure them to wall studs.

- Brick/Concrete: Use masonry drill bits and wall plugs or sleeve anchors. For heavy signs, concrete screws provide a strong hold.

- Metal: Use self-tapping screws or bolts, often with pre-drilled holes.

- Screws and Wall Plugs: Mark your drilling spots, ensure they are level, drill pilot holes, insert plugs, and then secure the sign with screws.

- Heavy-Duty Adhesives: For lighter signs or where drilling isn't an option, industrial-strength adhesives can be effective. Always clean and dry the surface thoroughly before application. Velcro is useful for signs that need to be changed frequently.

- Multi-Part Signs: For signs with individual letters, use a paper template to mark each letter's position accurately before drilling or applying adhesive to ensure proper spacing and alignment.

- Safety: When working at heights or with heavy signs, always have a helper. For construction sites, our Danger Construction Signs are available at Bunnings to ensure safety compliance.

How to Install Signs on Posts (In-Ground)

Post-mounted signs are ideal for property entrances and roadside warnings.

- Grass and Soil Installation: Use a post driver to drive the post into the ground, using a level to ensure it's plumb. For larger or permanent installations, digging a hole and setting the post in concrete offers superior stability.

- Concrete and Asphalt Installation: Drill holes with a masonry or asphalt-specific bit, insert anchor bolts, then position the post over the anchors and tighten the nuts.

- Breakaway Posts: If a sign is in a roadway's clear zone, a breakaway post is often legally required. These posts are designed to shear off on impact, minimising vehicle damage and injury risk.

- Roadside Safety: You must get permission from the relevant road authority (e.g., local council, state road agency) before installing signs within a road right-of-way. Always check local requirements.

- Farm Safety: For agricultural clients, robust post-mounted signs are essential. Learn more about farm safety signs and how they keep your property accident-free.

How to Install Signs Using Temporary and Portable Bases

For situations requiring flexibility, portable solutions are invaluable.

- Weighted Bases: These provide stability without permanent installation. They are perfect for temporary traffic management or event signage.

- A-Frames: Our Metal A-Frame signs are double-sided, lightweight, and easily transportable, making them ideal for storefronts and temporary warnings.

- Swing Stands: These signs offer a versatile solution for temporary traffic management and demarcation.

- Use Cases: Portable solutions are excellent for worksite warnings like "Wet Floor" signs. Explore our range of wet floor signage for essential types and placement.

Special Considerations for Electrical and Illuminated Signs

Illuminated signs offer high visibility but require expertise and strict adherence to safety protocols.

- Safety Precautions: Always disconnect the power supply before working on electrical signs. We recommend partnering with a licensed electrician to ensure compliance with Australian wiring codes.

- Raceway Mounting: Many illuminated signs are mounted on a "raceway," an enclosure for wiring and electrical components. This simplifies installation. Inspect the sign on arrival. Mark and pre-drill mounting and power holes. Unpack carefully, lifting by the raceway. Mount the raceway, ensuring it's level, and have a licensed electrician make the final power connection.

- Hiding Wiring: For a professional finish, conceal all wiring within the raceway, wall, or conduit.

- Testing: Always test electrical components before final mounting.

- High Visibility: Our Illuminated Stock Ahead Signs use LEDs to improve road safety in low-light and adverse weather conditions.

Post-Installation: Checks, Maintenance, and Longevity

After installation, a final check ensures your sign is safe, visible, and built to last. This quality control step protects your investment and keeps your message clear.

Final Installation Checks

Before finishing, take a few minutes to confirm everything is in order. Perform a stability test by giving the sign a gentle shake, especially for larger signs. Ensure all bolts, screws, or adhesive points are fully secure.

Next, step back and view the sign from various angles and distances. Check for obstructions like tree branches or parked vehicles. For multi-part signs, double-check that all components are correctly aligned and spaced. Use your spirit level one last time to confirm perfect level and alignment.

Finally, wipe down the sign face with a soft cloth to remove any fingerprints or dust for a pristine, professional appearance.

Long-Term Sign Maintenance

Regular maintenance is what separates signs that last for years from those that fail prematurely. Most maintenance is straightforward.

Cleaning is your first line of defence. Clean your sign periodically with mild soap and water and a soft cloth to avoid scratching the sign face.

After severe weather, inspect your signs for damage. Look for loose fixings, cracks, or fading. Addressing these issues early prevents small problems from becoming expensive replacements.

Make it a habit to check all mounting hardware for rust or loosening, and tighten any loose fasteners. For illuminated signs, ensure all electrical connections are sound and lights are functioning correctly. Always consult a licensed electrician for electrical work.

At Pinnacle Signage, we use durable, weather-resistant materials designed for the Australian climate. Even the toughest signs benefit from regular checks to maximise their lifespan. For more insights, read our tips for durable signage solutions.

Frequently Asked Questions about Sign Installation

Here are some of the most common queries we receive about installing signs in different situations, along with our expert recommendations.

How do I install a sign on a fence?

The approach depends on the fence type and sign weight.

For lightweight signs like corflute, heavy-duty zip ties are a quick and secure option on wire mesh or picket fences. Use enough ties to prevent sagging and pre-drill holes in the sign for easier installation.

For a more permanent solution, especially on timber or metal fences, bolts provide superior security. Drill through both the sign and the fence post, then secure with nuts and washers.

For chain-link fences, specialised sign brackets attach signs securely without damaging the fence.

Regardless of the method, mount the sign flush against the fence. A sign that sticks out can act like a sail in the wind, leading to damage.

What's the best way to hang a sign from the ceiling?

Ceiling-mounted signs are great for visibility in large spaces like warehouses or retail stores, but installation requires careful attention to structural integrity.

Use durable chains or steel cables rated for significantly more than the sign's actual weight. This safety margin is non-negotiable. The anchors must be installed into structural elements like joists, beams, or concrete slabs, never into a suspended ceiling grid, which cannot support the load.

Ensure even weight distribution across all hanging points to prevent tilting. For large or heavy signs, have a building professional confirm the ceiling's load-bearing capacity before you begin.

Can I install a large or heavy sign by myself?

No. Attempting to install a large or heavy sign solo is a significant safety risk that we strongly discourage. While smaller signs can be a DIY project, the equation changes with substantial size or weight.

Large signs are awkward and deceptively heavy. A momentary loss of balance can lead to serious injury or property damage. Most large sign installations require at least two people for control and stability.

Professional installers also have specialised equipment like lifts and cranes, which are often the only safe way to handle certain installations.

For any sign that is large, heavy, requires working at height, or involves electrical connections, we strongly recommend hiring professional sign installers. Their expertise ensures the job is done safely, securely, and in compliance with all regulations.

Get the Right Signs for a Flawless Installation

A successful installation starts with choosing quality signs built for the Australian environment.

At Pinnacle Signage, we manufacture high-quality, durable signage products right here in Australia. Our commitment to premium materials means you get a solution that's ready to perform. We provide a range of options, from safety signs, general information signs, or custom solutions with options for custom text, logos, and colours to match your requirements.

Pinnacle Signage products are now conveniently available at Bunnings, both in-store and online across Australia. This partnership makes accessing our quality signs easier than ever. Need a First Aid sign for a quick installation? You can pick up a Pinnacle 600 x 400mm Poly First Aid Sign on your next trip to Bunnings. For a broader look at what's available, find Pinnacle Signage products at your local Bunnings.

For bulk orders or specific customisation needs, our team in East Wagga Wagga, NSW, is ready to help. We can create signs with custom text, logos, and colours to match your requirements. You can also pick up your order directly from our warehouse at Unit 4/28 Nagle Street, East Wagga Wagga NSW, Monday to Friday, 8 am to 5 pm.

Explore our full range of safety and general signage to find the perfect signs for your business. If you have any questions about installing signs or need assistance with your project, don't hesitate to contact us. We're here to help you achieve mounting mastery!