All About Caution Signage: Options and Tips

Why Caution Signage is Essential for Australian Workplaces

Caution Signage serves as your first line of defence against workplace accidents, warning people about potential hazards that could cause minor to moderate injury. Here's what you need to know:

- Purpose: Alerts workers and visitors to hazards like wet floors, moving equipment, or uneven surfaces

- Colour Standard: Yellow background with black text and symbols

- Material Options: Aluminium, vinyl, polycarbonate, and reflective materials

- Common Types: Floor stands, wall-mounted signs, adhesive labels, and barricade tape

- Compliance: Must meet Australian Standards (AS 1319) and workplace safety regulations

Every workplace contains hazards that require clear visual warnings. Whether it's a slippery floor in a retail store, forklift traffic in a warehouse, or temporary roadworks on a construction site, caution signage helps prevent accidents before they happen.

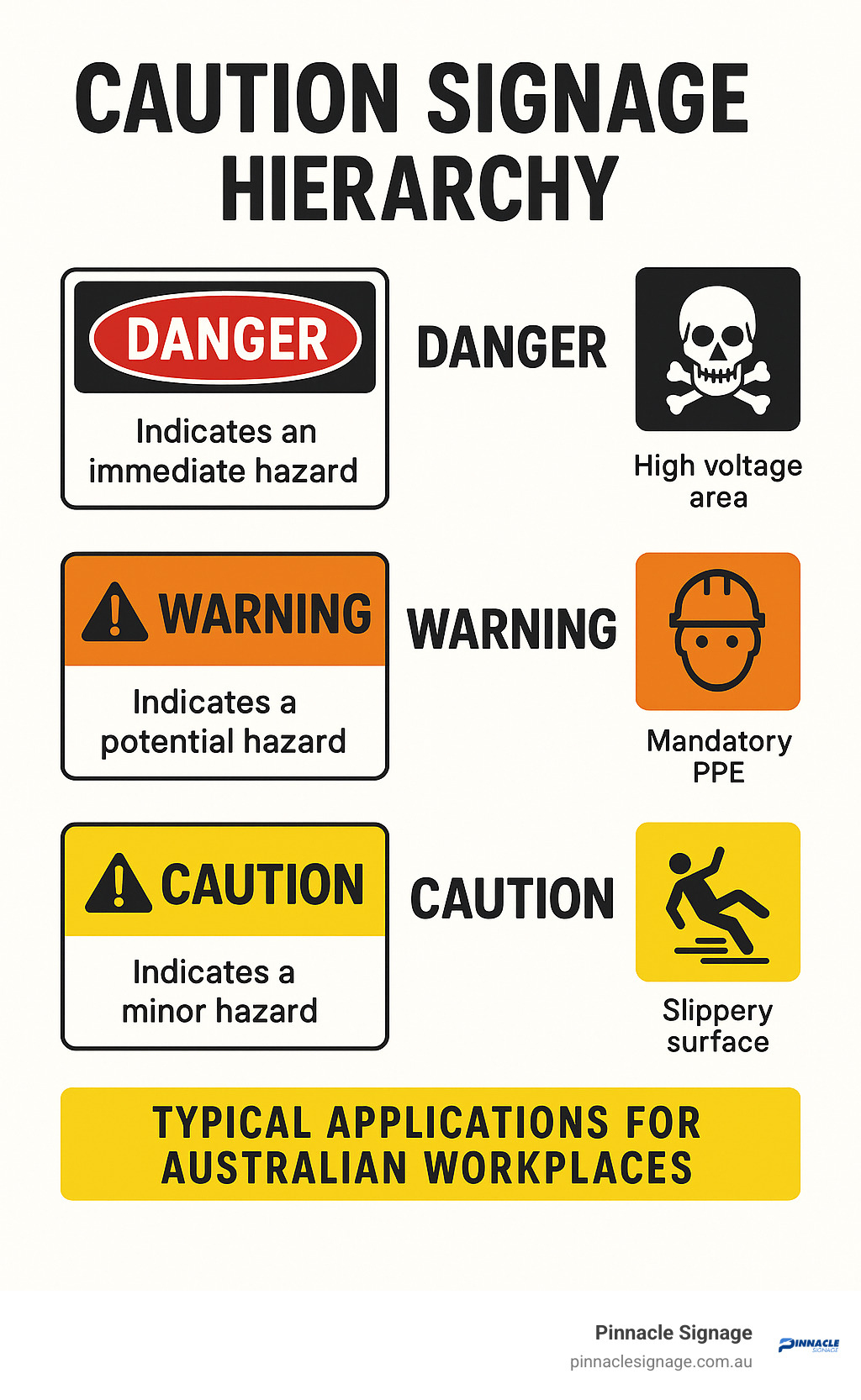

Caution signs differ from warning and danger signs in their level of urgency. While danger signs indicate immediate threats that could cause death or serious injury, caution signage addresses less severe but still important risks.

The effectiveness of caution signage depends on choosing the right materials, proper placement, and ensuring compliance with Australian workplace safety standards. Reflective materials boost visibility in low-light conditions, while durable substrates like aluminium withstand harsh outdoor environments.

Understanding Caution Signage Basics

Caution Signage sits between notice signs and danger signs in the safety hierarchy. These yellow and black warnings address real hazards without causing panic, alerting you to potential risks that could result in minor to moderate injury.

The yellow and black colour coding isn't just design choice—this combination has been scientifically proven to grab attention whilst indicating a moderate level of hazard. The bright yellow background ensures high visibility from a distance, while the black text provides the contrast needed for easy reading.

According to OSHA Standard 29 CFR 1910.145, caution signs warn against potential hazards or unsafe practices. This definition helps you understand exactly when Caution Signage is the right choice.

Getting the readability right is crucial for effectiveness. Text must be large enough to read from your intended viewing distance—typically 25mm high for every 3 metres of viewing distance.

The most effective caution signs include the signal word "CAUTION" displayed prominently, a safety alert symbol when required, and a concise legend. Pictograms work brilliantly because they transcend language barriers—particularly valuable in Australia's multicultural workplaces.

When to Deploy Caution Signage

Knowing when to use Caution Signage comes down to conducting a proper risk assessment. You're looking for situations where people might encounter risks that can be avoided simply by being aware they exist.

Classic scenarios include slip, trip, and fall zones like wet floors or uneven surfaces, moving equipment areas such as forklift traffic zones, and environmental hazards like hot surfaces or low overhead clearance.

The key distinction is injury severity. Use caution signs when the hazard could cause injuries like bruises, minor cuts, or sprains. If you're dealing with potential broken bones or serious injuries, you need warning signs. Reserve danger signs for situations that could be immediately life-threatening.

For a detailed breakdown, see our guide on Caution vs Danger vs Warning: What's the Difference?

Key Elements of Effective Caution Signage

Effective Caution Signage follows design principles based on solid human factors research. The signal word "CAUTION" needs prominent display, typically in the upper panel where eyes naturally go first.

Text legibility depends on several factors. Sans-serif fonts like Arial provide better readability than decorative fonts. Your text height should be minimum 6mm per metre of viewing distance, with adequate stroke width and luminance contrast between text and background of at least 70%.

Pictograms serve as universal hazard communicators, brilliant for Australian workplaces with team members from different countries. These symbols should follow international standards and be sized appropriately.

Keep your message panel concise and action-oriented. Instead of "Caution: Floor May Be Slippery," use "Caution: Slippery When Wet." This provides clearer, more immediate understanding.

Types of Caution Signs & Typical Uses

When it comes to Caution Signage, there's a format for virtually every workplace hazard situation you'll encounter.

Floor stands and A-frames are the workhorses of temporary hazard management. They're incredibly portable, visible from multiple angles, and stable enough to withstand occasional bumps. Perfect for cleaning staff who need to quickly deploy and pack away signs.

Wall-mounted panels provide reliable, long-term solutions for permanent hazards like low beams or hot water pipes. Made from durable aluminium or polycarbonate, they'll keep warning people for years without fading.

Adhesive labels pack a punch for equipment marking and close-up hazard identification. They're cost-effective when you need dozens of identical warnings for machines or chemical containers.

Cone toppers transform ordinary traffic cones into specific hazard communicators, telling people exactly what they're being protected from rather than just blocking an area.

Barricade tape creates continuous hazard boundaries for marking off larger areas during maintenance or construction work.

Different industries have developed their own patterns. Construction sites focus on machinery operation warnings and uneven ground alerts. Hospitality venues emphasise wet floor warnings and hot surface alerts. Healthcare facilities use caution signs for low-level radiation areas and patient lift equipment zones.

Caution Signage in Construction Sites

Construction sites present unique challenges because hazards change daily and signs need to withstand everything from concrete dust to sudden weather changes.

Heavy machinery operations create common caution signage needs. Signs like "Caution: Machinery Operating" give pedestrians and workers the heads-up to stay alert and maintain safe distances.

Open trenches and excavations that don't require danger-level warnings still need clear caution signage around their perimeters, working with physical barriers to prevent accidents.

PPE reminders often work best in caution format. Signs like "Caution: Hard Hat Required Beyond This Point" reinforce safety protocols without suggesting imminent threat.

Durability requirements are significant. Signs need UV-resistant inks, sturdy substrates, and mounting systems that handle vibration. Reflective materials become important for low-light conditions.

For comprehensive coverage, see: Caution Signs You Can't Miss on a Construction Site (Full Guide)

Road & Traffic-Related Caution Signage

Road applications represent some of the most demanding uses for Caution Signage. These signs must communicate clearly to drivers at various speeds and remain visible in all weather conditions.

Temporary works signage gives drivers advance notice to adjust behaviour before entering work zones. "Caution: Road Work Ahead" provides crucial buffer time for speed reduction and increased awareness.

Uneven surface warnings prevent vehicle damage and help drivers maintain control. Whether "Caution: Rough Road" or "Caution: Speed Humps Ahead," these signs help drivers adjust appropriately.

Reflectivity requirements are particularly stringent for road signage, typically using high-intensity prismatic reflective materials that perform reliably in vehicle headlights from significant distances.

For detailed information: Road Hazard Signs Explained: Know Before You Go

Choosing the Right Materials & Reflectivity

Getting your Caution Signage materials right makes the difference between signs that last years and ones that fail within months. Australia's challenging climate demands smart material choices that balance durability, visibility, and cost.

Aluminium stands as the workhorse of permanent outdoor caution signage. Its natural corrosion resistance and dimensional stability through temperature changes makes it ideal for long-term installations.

Reflective aluminium combines proven durability with retroreflective sheeting that transforms signs in low-light conditions. Light hits microscopic glass beads or prismatic structures and bounces straight back, creating visibility from much greater distances.

Polycarbonate brings serious impact resistance. If your signs might cop knocks from forklifts or trolleys, this material absorbs impacts that would dent aluminium whilst maintaining clear optical properties.

Vinyl delivers excellent value for short to medium-term applications. Quality products handle 5-7 years in Australian outdoor conditions when properly applied.

UV resistance isn't optional in Australia—it's essential. Quality materials incorporate UV stabilisers preventing colour fade and breakdown. Look for materials with genuine Australian condition ratings and minimum 5-year warranties.

Reflective vs Non-Reflective Caution Signage

Choosing between reflective and non-reflective Caution Signage depends on your lighting conditions and visibility requirements.

Reflective caution signage excels in low-light environments like warehouses with inconsistent lighting or outdoor areas without street lights. Research shows retroreflective materials can improve sign visibility by up to 500% in low-light conditions—the difference between visibility from 30 metres versus 150 metres.

Non-reflective signage performs perfectly in well-lit indoor environments with consistent lighting. These signs cost significantly less and avoid potential glare issues under bright fluorescent lighting.

Night-time visibility requirements often make the decision for you. Construction sites, car parks, and roadwork zones typically mandate reflective signage for 24-hour visibility.

Matching Material to Environment

Your specific environment should drive every material decision for Caution Signage.

Wet areas like commercial kitchens demand materials that resist moisture absorption and maintain strong adhesion in humid conditions. Polycarbonate and marine-grade aluminium excel here.

Chemical exposure environments need materials that resist specific workplace chemicals. Manufacturing facilities might require specialised coatings that won't degrade when exposed to acids or solvents.

High-heat zones near furnaces or processing equipment demand materials rated for liftd temperatures. Standard vinyl fails around 65°C, whilst specialised materials handle 150°C or higher.

Lifespan expectations vary dramatically. Indoor vinyl typically delivers 7-10 years, outdoor vinyl manages 3-5 years, aluminium with quality coatings lasts 10-15 years, and reflective materials generally offer 7-10 years depending on application demands.

Compliance: Australian Standards, OSHA & ANSI Explained

Getting your Caution Signage compliance right protects your business from legal issues whilst creating safer workplaces. Australian workplaces need to steer several standards, but the basics are straightforward.

AS 1319 forms the backbone of Australian workplace signage requirements, covering everything from colour codes to symbol designs. The yellow and black colour scheme for caution signs comes directly from this standard.

Safe Work Australia obligations go beyond just hanging signs. Employers must provide clear information about workplace hazards, and caution signage plays a crucial role in this visual communication system.

OSHA 29 CFR 1910.145 and ANSI Z535 standards align closely with Australian requirements, so compliance with one often means compliance with others. This global consistency means workers can recognise hazard warnings regardless of previous workplace experience.

Worker training requirements mean ensuring your team understands what different sign types mean and how to respond appropriately. Record-keeping during safety audits shows you're taking a systematic approach to workplace safety.

Caution Signage & Regulatory Penalties

Non-compliance with Caution Signage requirements can result in serious financial penalties. Workplace safety regulators impose fines ranging from hundreds to thousands of dollars per violation, with repeat offences attracting higher penalties.

When workplace accidents occur, investigators scrutinise whether appropriate caution signage was in place. If proper signage could have prevented an incident, you might face findings of employer negligence, turning accidents into serious legal problems.

Insurance companies also pay attention to these findings. Many policies require compliance with safety standards as coverage conditions. Non-compliance might result in higher premiums or claim rejections.

Building a due diligence defence requires demonstrating you took reasonable steps to prevent safety violations. Proper caution signage installation, maintenance, and worker training form key elements of this documentation.

For detailed guidance, the Safe Work Australia website provides comprehensive information for Australian businesses.

Incorporating Caution Signage into Safety Management Systems

Smart businesses integrate Caution Signage systematically into broader safety management approaches rather than treating it as an afterthought.

Risk registers should document exactly where caution signage is required based on hazard identification processes. This ensures no hazards slip through the cracks and provides clear justification for signage decisions.

Audit schedules must include caution signage condition and placement checks. Monthly inspections can identify faded, damaged, or missing signs before they compromise safety.

Staff inductions should include training about caution signage meaning and appropriate responses, plus procedures for reporting damaged signs. This creates culture where everyone takes responsibility for signage effectiveness.

Change management procedures must consider signage implications whenever workplace layouts or processes change. New hazards require new signage, whilst eliminated hazards should have obsolete signage removed to avoid confusion.

Placement, Customisation & Maintenance Best Practices

Getting your Caution Signage placement right makes the difference between effective hazard communication and wasted investment.

Eye-level mounting works best for most applications. Position signs between 1.5-2.0 metres above floor level for pedestrians, or 2.5-3 metres for forklift operators and truck drivers.

The line-of-sight principle requires clear visibility from the direction people approach the hazard. Signs become useless if equipment, structural columns, or other signs block the view from critical approach angles.

Distance legibility calculations help choose the right sign size. The standard rule of 25mm letter height for every 3 metres of viewing distance works in good lighting, but you might need larger text in warehouses with poor lighting.

Australia's multicultural workforce often benefits from multi-language text on caution signage. The specific languages depend on your team—Mandarin, Arabic, or Pacific Island languages might be relevant depending on your workforce.

Cleaning routines shouldn't be complicated but need to suit the material. Mild soap solutions work well for most signs, but avoid abrasive cleaners on reflective surfaces—they'll destroy retroreflective properties.

Smart sign life-cycle planning means anticipating replacement needs before signage fails. Indoor vinyl might last 7-10 years, whilst outdoor applications typically need replacement every 3-5 years.

Custom Caution Signage that Works

Custom Caution Signage provides flexibility to address unique workplace hazards whilst maintaining professional appearance and regulatory compliance.

Company branding can be subtly integrated without compromising safety message clarity. Your logo and consistent colour schemes help reinforce professional image whilst ensuring cohesive signage across facilities.

Specific hazard legends become essential when standard messages don't adequately address unique risks. Messages like "Caution: Automated Guided Vehicle Route" provide precise hazard communication that generic signs can't match.

QR codes add modern functionality by linking directly to Safety Data Sheets or detailed procedures. Workers can quickly access comprehensive information using smartphones, particularly valuable for complex hazards.

For comprehensive guidance: More info about designing custom signs

Maintaining Visibility Over Time

Caution Signage effectiveness deteriorates without proper maintenance. Australian climate is particularly harsh, with intense UV radiation and weather variations that quickly degrade even high-quality materials.

Scheduled inspections should occur monthly for critical safety signage. Create checklists covering text legibility, colour retention, physical damage, mounting security, and obstruction by equipment.

Replacement criteria help make consistent decisions about when signs need updating. Key indicators include colour fading beyond 70% of original intensity, reduced text legibility, physical damage affecting message clarity, and mounting system failure.

Process change updates require signage review whenever workplace layouts or procedures change. New hazards need appropriate signage, whilst eliminated risks should have obsolete signs removed to prevent confusion.

Cost, Bulk Buying & Quality Checks

Smart purchasing strategies for Caution Signage can deliver significant savings whilst ensuring signs meet safety standards and perform reliably in Australian conditions.

The economics become interesting with per-unit pricing. A single custom caution sign might cost $45-60, but order 50 of the same design and you're looking at $15-25 each. This dramatic reduction happens because setup costs get spread across larger quantities.

Economies of scale extend beyond manufacturing. Design costs become negligible across multiple units. Freight charges, which can represent 10-15% of total investment, drop significantly per unit with consolidated orders.

Wholesale discounts typically kick in around 25-50 pieces, reducing total project costs by 20-40% compared to small-quantity pricing. For businesses with multiple sites, these savings add up quickly.

Quality assurance becomes critical with larger quantities. Material certification should provide clear AS 1319 compliance documentation. Ink adhesion testing ensures printed elements won't peel under Australian UV conditions. Reflectivity measurements verify retroreflective materials perform as specified.

Sample kits offer invaluable peace of mind before committing to large orders, letting you evaluate material quality and colour accuracy in your actual environment.

The return on safety investment often surprises business owners. Even preventing a single minor workplace injury can save thousands in medical costs and workers' compensation claims.

Ensuring You Buy High-Quality Caution Signage

Distinguishing between professional-grade Caution Signage and inferior alternatives requires understanding key performance indicators.

Material certification documentation should include comprehensive standards compliance verification, including AS 1319 compliance and UV resistance test results showing colour retention after years of equivalent outdoor exposure.

UV-tested inks represent one of the most critical quality factors for Australian conditions. Our intense sunlight can fade inferior inks within months. Quality suppliers provide accelerated weathering test results demonstrating colour retention.

Compliance marks from recognised testing laboratories provide independent verification of sign performance. Marks from organisations like SAI Global offer assurance that signs meet claimed specifications.

Supplier reputation indicators include years of safety signage specialisation, customer references from similar businesses, and technical support capabilities for complex applications.

Savings from Bulk Orders & Standardisation

Strategic purchasing approaches for Caution Signage can deliver substantial cost savings whilst improving safety program consistency.

Project roll-outs benefit enormously from coordinated purchasing that combines requirements across multiple phases or sites. This maximises quantity discounts whilst ensuring consistent signage standards, potentially reducing total costs by 30-50%.

Multi-site businesses achieve greatest savings through standardisation. When your Perth warehouse uses the same caution signs as your Brisbane facility, you leverage combined purchasing power whilst simplifying maintenance programs.

Reduced freight costs represent significant savings opportunities. Consolidating orders into larger shipments cuts freight expenses dramatically, particularly for businesses with multiple locations.

Volume purchasing agreements with preferred suppliers can lock in favourable pricing for ongoing requirements whilst ensuring consistent quality and service levels.

Frequently Asked Questions about Caution Signage

How big should a caution sign be for warehouse aisles?

Warehouse Caution Signage size depends on viewing distance and movement speed. For forklift areas, signs need clear readability from at least 10 metres—meaning your "CAUTION" header needs at least 85mm height.

Most warehouses find 300x200mm signs work well for standard applications, whilst 450x300mm provides better visibility in busier areas. For long sight lines or high-speed zones, 600x400mm ensures nobody misses your warning.

Mount signs at forklift operator eye level—typically 2.5-3 metres high. For really long aisles where racking blocks visibility, multiple signs ensure complete coverage.

Do I need bilingual caution signage on every construction site?

While there's no blanket legal requirement for bilingual Caution Signage on every Australian construction site, it's often the smart choice—and sometimes required depending on contracts and workforce.

Major projects frequently mandate bilingual signage as part of safety management plans, especially with subcontractors whose workers speak limited English. Common combinations include English paired with Spanish, Mandarin, or Arabic.

Construction sites are incredibly multicultural environments. When safety depends on understanding warnings, you want to eliminate miscommunication chances. The cost of adding a second language is minimal compared to potential incident costs.

The most effective approach combines clear pictograms with bilingual text, providing universal hazard recognition regardless of language skills.

How often should caution signs be replaced in outdoor environments?

Outdoor Caution Signage should give 5-7 years of reliable service in Australian conditions before needing replacement, but staying on top of condition is key rather than waiting for complete failure.

Australia's intense UV radiation is particularly harsh, causing colours to fade and materials to break down. Add temperature extremes and sudden weather changes, and outdoor signs need regular attention.

Monthly visual inspections are your best defence. Look for text becoming hard to read from normal distance, colours faded to less than 70% original intensity, or physical damage affecting message clarity. For reflective signs, check whether they still light up properly in torchlight.

Environmental factors make huge differences to lifespan. Coastal locations with salt air, industrial areas with pollution, or sites with extreme temperatures will accelerate deterioration, potentially requiring replacement every 3-4 years instead of the standard 5-7.

Conclusion

When protecting your workplace and people, Caution Signage isn't just a compliance checkbox—it's your first line of defence against preventable accidents. Getting it right means understanding the difference between caution, warning, and danger signs, then choosing appropriate materials and placement for your environment.

Proper caution signage works through simplicity. A well-placed "Caution: Wet Floor" sign prevents slips before they happen. Clear "Caution: Forklift Traffic" warnings keep pedestrians alert in busy warehouses.

Material selection makes or breaks your signage investment. Cheap vinyl might save $20 upfront, but when it fades after six months in Queensland sun, you're back to square one with safety gaps and replacement costs. Quality aluminium with proper UV-resistant coatings costs more initially but protects your people for years.

Australian conditions demand signage that handles punishment. Reflective materials become essential in low-light areas, whilst polycarbonate substrates resist impact in high-traffic zones. Matching material choice to environment isn't optional—it's the difference between signage that works and signage that fails when needed.

Compliance with AS 1319 and workplace safety regulations protects you from more than fines. It demonstrates due diligence, supports insurance claims, and ensures your signage actually communicates hazards effectively.

Bulk orders can cut per-unit costs by 30-40% whilst ensuring consistency across your site. Whether fitting out new warehouses or upgrading across multiple locations, coordinated purchasing makes financial sense. Standardised designs also simplify maintenance and replacement.

At Pinnacle Signage, we've perfected Caution Signage solutions for Australian conditions. We understand that Darwin construction sites face different challenges than Melbourne retail stores. Our materials are tested for Australian conditions, our designs comply with local standards, and our team knows what works in real applications.

Customisation doesn't mean compromise. We create signage addressing your specific hazards whilst maintaining full compliance. Whether you need bilingual warnings for multicultural workforces, company branding integration, or specialised messages for unique hazards, we'll design solutions that work.

Our nationwide coverage means consistent support whether you're managing single sites or coordinating across Australia. Fast turnaround keeps projects on schedule, whilst our quality assurance ensures every sign meets standards before leaving our facility.

Ready to upgrade your workplace safety with professional Caution Signage that actually works? Browse our complete range and see how proper hazard communication can transform your safety outcomes: More info about custom caution signage

Contact our team today to discuss your specific requirements. We'll help you choose the right signage solutions for your environment, budget, and safety goals.