Need Electrical Safety Signs? What They Mean and How to Buy Online Easily

The Critical Role of Electrical Safety Signage

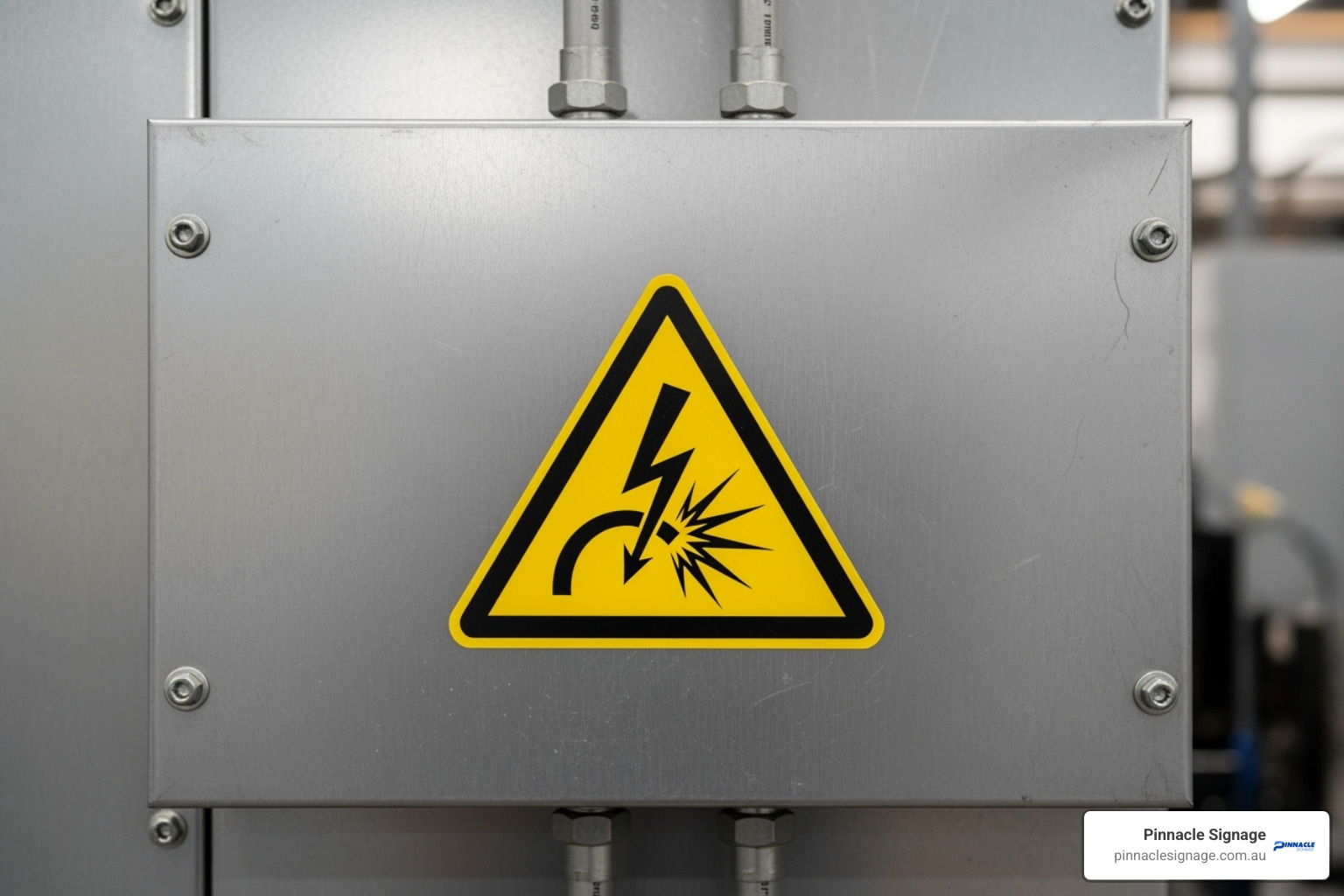

Electrical safety signs are essential visual tools that communicate hazards and safety procedures, protecting workers and visitors from life-threatening electrical dangers. Using standardised colours, symbols, and text, they instantly convey risks such as high voltage, arc flash hazards, and restricted access areas.

Key Types of Electrical Safety Signs:

- Danger Signs (Red): Indicate life-threatening hazards like high voltage equipment.

- Warning Signs (Orange/Yellow): Alert to potential risks that could cause serious injury.

- Caution Signs (Yellow): Advise of minor hazards that require attention.

- Mandatory Signs (Blue): Specify required actions, such as "Authorised Personnel Only."

- Prohibition Signs (Red circle with a line): Forbid actions near electrical equipment.

In Australia, electrical hazards cause hundreds of serious workplace injuries and dozens of fatalities each year. Incidents like arc flashes, which can generate temperatures hotter than the sun's surface, underscore why proper signage is not just a recommendation—it's a critical part of your duty of care.

A single moment of confusion around electrical equipment can lead to electrocution, severe burns, or death. Electrical safety signs act as silent guardians, providing clear, instant communication when it matters most. A well-placed and easily understood sign can be the difference between a near-miss and a devastating accident, protecting your team and your business.

Electrical safety signs terms at a glance:

At Pinnacle Signage, we understand that clear visual communication is a cornerstone of any effective workplace safety program. Our commitment is to help you create a safer environment by providing high-quality, compliant signage that protects your team from preventable incidents.

A Practical Guide to Electrical Safety Signs in the Workplace

Understanding electrical safety signs is straightforward. They are your workplace's way of constantly communicating vital information to keep people safe. Let's break down how these silent guardians work to prevent accidents.

Common Electrical Hazards Signs Warn Against

Electrical safety signs make invisible dangers visible. They serve as an early warning system for some of the most serious risks in any workplace.

- Electrocution: The most severe risk. "Danger: High Voltage" signs mark areas where contact with an electrical circuit could be fatal in seconds.

- Arc Flash: An electrical explosion that can reach temperatures of 19,000°C, causing devastating burns and injuries from several metres away without any physical contact.

- Electrical Fires: Often starting inside walls or equipment, these fires are particularly dangerous as using water can be deadly.

- High Voltage Equipment: From a 240-volt supply to an 11,000-volt industrial system, the danger escalates with the voltage.

- Buried and Overhead Cables: These create hidden dangers for excavation crews and anyone operating tall equipment.

- Static Electricity: In areas with flammable gases or volatile chemicals, a simple static spark can trigger an explosion. Battery charging areas are particularly vulnerable.

These signs make hidden electrical dangers impossible to ignore.

The Visual Language of Electrical Safety Signs: Colours and Symbols

The effectiveness of electrical safety signs lies in their universal visual language, which communicates critical information instantly.

- Danger Signs (Red): Signal the most serious hazards where death or serious injury is likely. The red background commands immediate attention.

- Warning Signs (Orange/Yellow): Indicate a hazard that could cause serious injury if not avoided. An "Arc Flash Hazard" sign is a common example.

- Caution Signs (Yellow): Alert to less severe risks that could cause minor injuries or equipment damage. A "Keep Electric Panel Area Clear" sign falls into this category.

- Notice and Mandatory Signs (Blue): Blue notice signs convey important procedural information, while blue mandatory signs with a circular background indicate an action you must take for safety.

- Safety Signs (Green): Point to the location of emergency equipment, exits, or first aid stations.

- Prohibition Signs (Red circle with a line): Clearly show what actions are forbidden.

Common symbols include the lightning bolt for general electrical danger and the electric shock symbol (lightning bolt striking a hand) for specific shock hazards.

You can learn more about the differences between sign types to better understand these visual cues.

Examples of Essential Electrical Warning Signs

These are some of the most common electrical safety signs you'll encounter and why they are so important for preventing accidents.

- High Voltage Signs: These red and white signs mark transformers and substations where voltage can kill instantly. Specifying the voltage (e.g., "Danger: 11000 Volts") provides critical clarity.

- Electrical Panel Clearance Signs: A message like "Keep 1 Metre Clear" ensures that authorised personnel and emergency responders have safe and immediate access to shut down power.

- Lockout/Tagout Signs: These signs are used with physical locks to prevent equipment from being re-energised during maintenance, protecting workers from accidental startup.

- Authorised Personnel Only Signs: They act as gatekeepers, ensuring only trained individuals enter areas with significant electrical hazards.

- Buried Cable Signs: Essential for any excavation work, these signs, combined with the "Dial Before You Dig" service, prevent catastrophic accidents.

- Battery Charging Area Signs: These address multiple hazards at once, including shock, chemical exposure, and explosion risks from hydrogen gas.

For more comprehensive information, check out our guide on how to stay current with the best electrical hazard warning signs.

Fulfilling Your Duty of Care

In Australia, workplace health and safety (WHS) laws require employers to manage risks and provide a safe environment. This is known as your duty of care. Using clear electrical safety signs is a critical part of fulfilling this responsibility.

Effective signage is a cornerstone of risk management. It communicates dangers, supports safe procedures, and helps build a strong safety culture. By ensuring your signs are clear and correctly placed, you demonstrate a commitment to protecting your team and meeting your WHS obligations.

Implementing Signage for a Safer Workplace

Installing your electrical safety signs is just the first step. To be effective, they must be placed thoughtfully and maintained properly so they can do their job of protecting people.

Best Practices for Placing and Maintaining Electrical Safety Signs

Effective sign placement ensures your warnings are seen at the right time.

- Visibility and Line of Sight: Signs must be completely unobstructed and placed along natural sight lines.

- Mounting Height: Eye level (typically 1.5 to 1.8 metres) is ideal. If signs are too high or too low, they can be easily missed.

- Proximity to Hazard: The closer a sign is to the actual danger, the more immediate and relevant its message. An arc flash warning should be placed directly on the electrical panel.

Regular maintenance is also essential. A faded or dirty sign can undermine your safety culture.

- Regular Inspection: Check for fading, damage, or loose mountings as part of your routine maintenance schedule.

- Cleaning: Keep signs free of dust, grease, and grime so they remain easy to read.

- Replacement: Replace faded or damaged signs immediately. A bright red "Danger" sign commands attention in a way a pale, worn-out one cannot.

Choosing the Right Signage and Partner

Quality matters when it comes to electrical safety signs. They are critical safety equipment that must perform reliably for years, often in challenging Australian conditions.

Sign materials play a huge role in longevity.

- Aluminium: Offers exceptional durability and weather resistance, making it ideal for outdoor or harsh industrial environments.

- Polypropylene: A lightweight yet robust alternative suited for indoor or sheltered outdoor areas, with good chemical resistance.

- Self-Adhesive Vinyl Labels: A versatile and durable option for applying warnings directly onto panels, machinery, and equipment surfaces. Laminated vinyl offers extra protection against abrasion and UV exposure.

At Pinnacle Signage, we focus on materials and construction methods that stand up to real-world Australian workplaces. We understand that every site has unique hazards and requirements. Whether you need signs with specific voltage warnings or custom combinations of symbols and text, we can create exactly what you need with fast turnaround times.

Choosing the right partner means getting high-quality signage that performs when it matters most. Learn more about how we're Making Your Workplace Safe and Secure with High-Quality Safety Signage.

Find the Right Signs for Your Site

Electrical safety signs are not just a compliance requirement—they are a fundamental part of keeping your workplace safe. From the bold red of a "Danger" sign to the clear instructions on a lockout tag, these visual cues are your first line of defence against unseen electrical hazards. They protect your team, your visitors, and your business from preventable accidents.

Ensuring your facility is correctly signed doesn't have to be complicated. A simple walkthrough of your site can help identify where warnings are missing or unclear. If you need to update your signage, we're here to help.

At Pinnacle Signage, we provide durable, high-quality electrical safety signs designed for Australian conditions. Whether you need standard warnings or custom solutions for your specific site, we have you covered.

Ready to improve safety at your workplace? We offer fast Australia-wide delivery to get your signs to you quickly.

Explore our Electrical Safety Signs and more on our website

Your team's safety is the best investment you can make.