Beyond the Dots: Making Sense of Universal Braille Signage

Why Universal Braille Signs Matter for Australian Buildings

Universal braille signs are tactile accessibility signs that combine raised lettering with braille dots, designed to help people with vision impairments navigate buildings independently and safely. In Australia, their use is a legal requirement under the National Construction Code (NCC) and Australian Standard AS 1428.1 for areas like toilets, exits, and spaces with hearing augmentation. Compliant signs have specific features, including raised sans-serif characters, Grade 2 Unified English Braille (UEB), high luminance contrast, and non-glare finishes. The specifications are precise, from the domed shape and spacing of braille dots to the strategic placement on the latch side of doors—not on the door itself. Using durable, weather-resistant materials is also crucial for both indoor and outdoor Australian conditions.

For managers of construction sites, commercial buildings, or public facilities, understanding these fundamentals is key to ensuring a project meets accessibility standards and creates a genuinely welcoming space for all visitors. Correct implementation from the start avoids costly retrofitting and demonstrates a commitment to inclusive design. This overview breaks down the essential information needed to make informed decisions regarding compliant accessibility signage.

The Anatomy of a Universal Braille Sign

When we talk about universal braille signs, we're referring to more than just dots on a surface, we're discussing a carefully designed system of tactile elements and visual cues that work together to provide essential information for everyone. Our primary goal with these signs is to foster independence and ensure that all individuals can steer public spaces with ease and dignity. The benefits extend beyond mere compliance, contributing to a more inclusive society and enhancing the overall experience for visitors and staff alike. From a practical standpoint, well-designed braille signs improve wayfinding, reduce confusion, and minimise potential hazards for those with vision impairments.

For an in-depth look at what makes these signs so crucial, you can explore our guide on What are Braille Tactile Signs? A Simple Guide to Accessibility. The design principles behind these signs are rooted in readability and a positive user experience, ensuring that the tactile elements and braille are clear, consistent, and easy to interpret.

Understanding Tactile Characters

Tactile characters are the raised letters and numbers you can feel on a sign. In Australia, these characters must adhere to strict guidelines outlined in AS 1428.1 to ensure they are legible for individuals with low vision or those who read by touch. Key specifications include:

- Height and Proportions: Raised characters should generally be between 15mm and 50mm in height. Their width-to-height ratio should typically fall between 3:5 and 1:1. These proportions ensure that characters are easily distinguishable by touch.

- Font Style: A sans-serif font is mandated for tactile characters. This is because sans-serif fonts have simpler, cleaner lines without decorative flourishes, making them much easier to read both visually and by touch.

- Stroke Thickness: The stroke thickness, or the width of the lines forming the characters, should be between 1:5 and 1:10 of the character's height. This balance prevents characters from feeling too thin or too bulky.

- Spacing Requirements: Proper spacing between individual characters, words, and lines of text is crucial. This prevents characters from merging together by touch and improves overall legibility for those with low vision.

These precise requirements ensure that the information conveyed through tactile characters is unambiguous, serving as a vital component of accessible wayfinding.

Decoding the Braille Component

The braille component of universal braille signs is perhaps the most critical for individuals who are blind. It provides the same information as the raised text, but in a tactile format that can be read by touch.

In Australia, the standard for braille on signage is Unified English Braille (UEB) Grade 2. Unlike Grade 1 braille, which is a letter-for-letter transcription, Grade 2 is contracted braille. This means it uses combinations of characters to represent common words, parts of words, and abbreviations, making it more efficient and faster to read for experienced braille users. This is why it's the preferred and mandated system for signage.

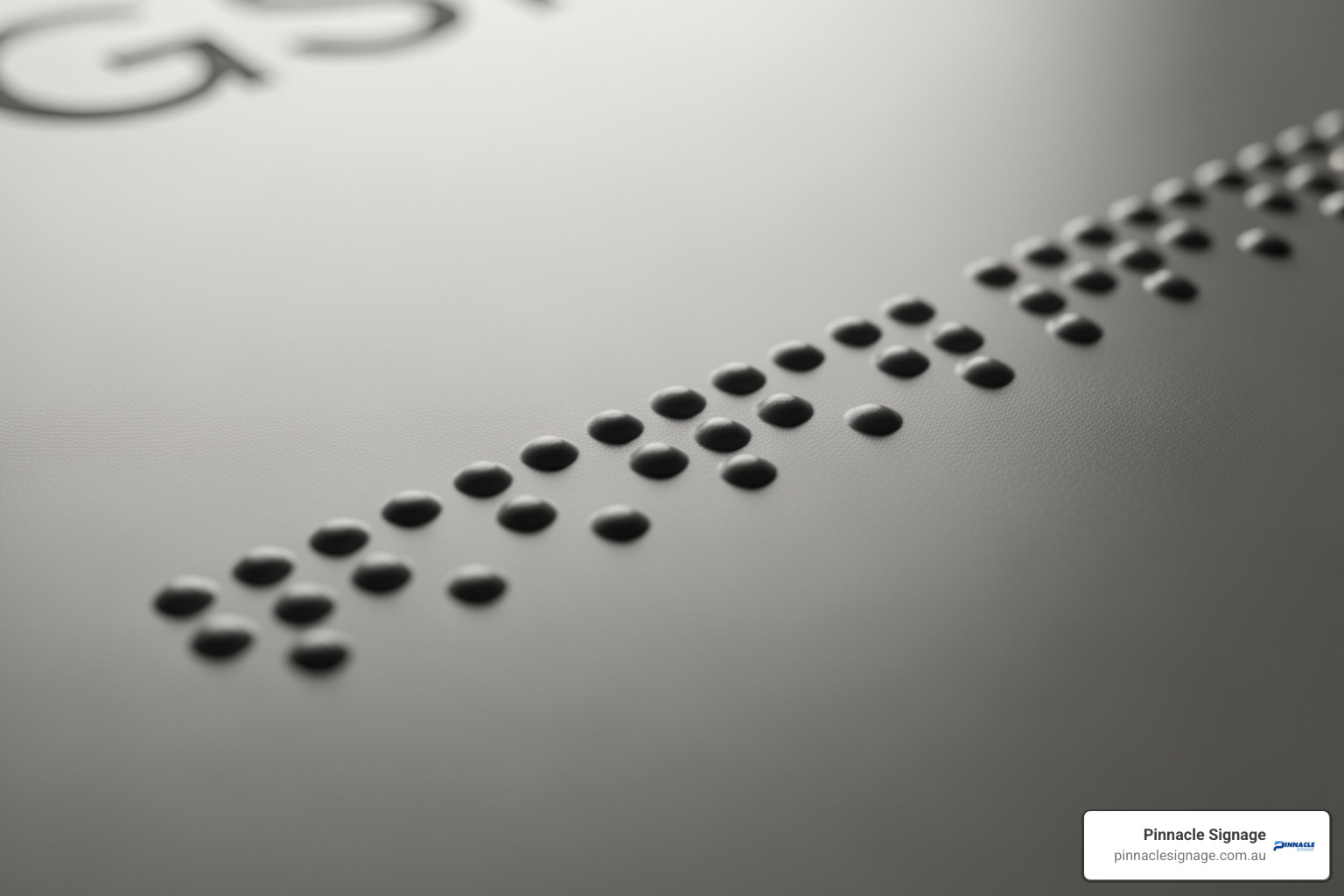

The physical specifications of the braille dots are just as important as the characters themselves:

- Dot Shape: Braille dots must be domed or rounded, not pointed or flat. This ensures they are comfortable to read by touch and reduces the chance of injury or discomfort.

- Dot Height: Each dot should have a height typically between 0.6mm and 0.9mm. This height provides sufficient tactile contrast against the sign's surface.

- Spacing: The spacing between dots within a single braille cell, and between adjacent cells, is carefully regulated. For instance, the distance between two dots in the same cell should be between 2.3mm and 2.5mm. Consistent and accurate spacing is paramount for braille readers to distinguish characters correctly.

- Placement: Braille must always be positioned directly below the corresponding tactile text. If there are multiple lines of text, the braille should be placed below the entire text block. Crucially, braille must be separated by at least 9.5mm from any other tactile characters, raised borders, or decorative elements to avoid confusion and allow for unobstructed reading.

Understanding these intricate details is vital for creating truly accessible signage. For more insights into Braille specifications, refer to our comprehensive guide on Braille Signage 101: Understanding Tactile Signs for Accessibility.

Critical Design Factors: Contrast and Finish

Beyond the tactile elements, the visual design of universal braille signs plays a significant role in their accessibility, particularly for individuals with low vision. Two key factors are paramount: contrast and finish.

- Luminance Contrast: This refers to the difference in light reflectance between the characters and the background of the sign. Australian standards require a high level of luminance contrast to ensure that the text and symbols stand out clearly. For example, dark characters on a light background, or vice versa, are essential. This greatly improves readability for people with varying degrees of vision impairment.

- Non-Glare Finish: All accessible signs, including braille signage, must have a non-glare finish. A matte finish prevents reflections from lighting, windows, or other shiny surfaces from obscuring the sign's information. Glare can make signs virtually impossible to read for anyone, but especially for those with vision impairments who may rely on subtle visual cues.

These design considerations are not just aesthetic choices, they are fundamental accessibility features that contribute to the overall visual clarity of the sign, making it usable for the widest possible audience. At Pinnacle Signage, we understand that these details are non-negotiable for enhancing accessibility and safety. Our commitment to meeting these precise requirements ensures our signs provide clear, easy-to-read information for all users. You can learn more about how we improve accessibility through our signs at Tactile Braille Signs at Pinnacle Signage: Enhancing Accessibility and Safety.

Correct Placement: Where and How to Install Universal Braille Signs

Even the most perfectly manufactured universal braille signs won't be effective if they aren't installed correctly. Proper placement is crucial for user accessibility, ensuring that individuals with vision impairments can easily locate and read the information. This involves adhering to specific mounting heights and locations, and maintaining consistency throughout a building or facility. Correct installation ensures compliance with the National Construction Code and relevant Australian Standards, making wayfinding intuitive and safe for everyone.

Mounting Height and Location Rules

The placement of accessible signage is highly regulated to ensure consistency and usability.

Here are the key guidelines we follow:

- Prescribed Height Range: Universal braille signs must be mounted at a specific height from the finished floor. In Australia, this typically means that the tactile characters should be positioned with their baseline between 900mm and 1200mm from the floor. This range is carefully chosen to be comfortable for most people to reach and read by touch.

- Latch-Side Placement: For signs identifying rooms or spaces with doors, the sign must always be mounted on the wall adjacent to the door, on the latch side. This is so that a person approaching the door can locate the sign before opening the door, without having to step into the swing path of the door.

- Clear Floor Space: There must be a minimum of 450mm of clear floor space directly in front of the sign. This ensures that a person using a wheelchair, a guide dog, or a long cane can approach the sign without obstruction.

- Unobstructed Access: The sign itself must be free from any obstructions such as door frames, furniture, or decorative elements. It needs to be clearly visible and accessible for reading by touch.

- Consistency: It's vital that placement guidelines are applied consistently throughout an entire building. Predictability helps users learn the layout and confidently steer independently.

Mastering these guidelines is essential for truly accessible environments.

Common Installation Mistakes to Avoid

Even with clear guidelines, some common errors can undermine the effectiveness of universal braille signs. We often see businesses making these mistakes, which can lead to non-compliance and hinder accessibility:

- Installing on Doors: A frequent mistake is mounting signs directly onto the door itself. This is incorrect because the sign moves with the door, making it impossible to read by touch while the door is opening or closing, and potentially creating a hazard. Signs must always be on the adjacent wall.

- Incorrect Height: Mounting signs too high or too low makes them inaccessible to many users. Consistently adhering to the 900mm to 1200mm range for tactile characters is crucial.

- Poor Lighting: While braille is read by touch, good lighting is essential for the tactile characters and visual contrast, especially for individuals with low vision. Signs placed in dimly lit areas will be less effective.

- Obstructions: Ensuring the area around the sign is free from obstructions is critical. Planters, rubbish bins, artwork, or even poorly placed furniture can block access to the sign, rendering it useless.

- Inconsistent Placement: If signs are placed in different locations or at varying heights throughout a building, it creates confusion and frustration for users. Uniformity in placement is key to predictable and independent navigation.

Avoiding these pitfalls ensures your investment in accessible signage genuinely serves its purpose and complies with Australian standards.

Materials and Manufacturing: Ensuring Durability and Quality

The materials and manufacturing processes behind universal braille signs are just as important as their design and placement. These factors directly impact the sign's longevity, readability over time, and its ability to withstand the rigours of various environments. Investing in high-quality signs means ensuring continuous accessibility and avoiding the need for frequent replacements, offering excellent long-term value.

Choosing the Right Materials

Selecting the appropriate materials for universal braille signs is fundamental to their performance and durability. We understand that these signs need to stand up to Australian conditions, whether they're indoors or out.

When considering materials, we look for:

- Durability: The signs must be robust enough to resist wear and tear from constant tactile interaction and general public use. This means choosing substrates that maintain their integrity without chipping, cracking, or fading.

- Weather Resistance: For signs installed in outdoor or semi-outdoor environments, resistance to UV radiation, moisture, and temperature fluctuations is paramount. Our signs are crafted from durable, weather-resistant materials to ensure they remain legible and intact for years, regardless of the climate.

- Vandal Resistance: In public spaces, signs can sometimes be subjected to vandalism. Materials that are difficult to scratch, deface, or remove are highly desirable.

- Compliance: Crucially, the materials must be suitable for creating precise tactile characters and braille dots that meet AS 1428.1 specifications.

Professional manufacturers specialise in high-quality, durable signage products that meet these stringent requirements. The goal is to provide solutions that are not only compliant but also built to last, ensuring long-term accessibility. For more information on compliant and durable material options, you can explore our article on Tactile Signage Solutions.

The Importance of Quality Fabrication for Universal Braille Signs

The fabrication process is where the design specifications of universal braille signs come to life. Precision engineering during manufacturing is non-negotiable to ensure that every dot and every character is perfectly formed and positioned.

Key aspects of quality fabrication include:

- Precision Engineering: The creation of braille dots and tactile characters requires extremely precise manufacturing techniques. Any deviation in dot height, shape, or spacing can render the braille unreadable. We use advanced processes to ensure absolute accuracy.

- Dot Integrity: The domed shape of each braille dot must be consistent and smooth. Poorly formed dots, or those with sharp edges, can be uncomfortable to read and may even cause injury.

- Tactile Feel: The overall tactile quality of the sign is critical. Both the braille and the raised characters should have a consistent and pleasant feel, allowing for easy and accurate reading by touch.

- Durability of Tactile Elements: The raised elements must be securely bonded to the sign's surface and durable enough not to wear down or detach over time. This ensures the sign remains functional for its intended lifespan.

- Compliance Assurance: Quality fabrication is the ultimate guarantee of compliance with Australian Standards. When signs are manufactured with meticulous attention to detail, you can be confident that they meet all legal requirements for accessibility.

Our manufacturing processes are designed to deliver premium products with exceptional quality control, ensuring that every universal braille sign from Pinnacle Signage is compliant, durable, and effective.

Beyond Compliance: The Future of Accessible Wayfinding

While ensuring compliance with current standards is essential, the landscape of accessible design is continuously evolving. The future of universal braille signs lies in integrating new technologies and embracing a broader universal design philosophy to create environments that are not just compliant but genuinely intuitive and inclusive for everyone.

Integrating Technology with Universal Braille Signs

The next generation of accessible wayfinding will likely see traditional braille signs improved by smart technologies. Imagine a future where universal braille signs are not just static markers but gateways to richer information:

- QR Codes: Integrating QR codes onto signs could allow users to scan with their smartphones to access audio descriptions, larger text, or information in multiple languages.

- Audio Descriptions: Signs could be equipped with near-field communication (NFC) tags or Bluetooth guides that trigger audio descriptions of the location or directions on a user's smartphone.

- Wayfinding Apps: Digital wayfinding apps could integrate with physical braille signs, offering real-time navigation assistance custom to individual accessibility needs.

- Digital Integration: In smart buildings, signs might connect to broader digital systems, allowing for dynamic updates or personalised information delivery.

These technological advancements promise to make navigation even more seamless and informative, working in conjunction with the foundational tactile and braille elements. The International Council on English Braille (ICEB) continues to develop and refine standards like Unified English Braille (UEB), ensuring that braille remains a robust and adaptable system for future innovations.

Creating a Truly Inclusive Environment

The goal of universal braille signs and accessible design is to create environments where everyone feels welcomed, respected, and capable of independent navigation. This goes beyond simply meeting minimum requirements, it's about fostering a culture of inclusivity.

By thoughtfully designing and implementing accessible signage, businesses and organisations can:

- Improve Dignity and Independence: Allowing individuals with vision impairments to steer public spaces independently is a profound act of respect, promoting self-reliance and confidence.

- Ensure a Positive User Experience: When accessibility is seamlessly integrated, it creates a more positive and less stressful experience for all visitors, not just those with specific needs.

- Demonstrate Social Responsibility: Commitment to accessibility reflects positively on an organisation's values, enhancing its brand reputation as a socially responsible entity.

- Welcome All Visitors: Truly accessible spaces are welcoming spaces, ensuring that no one is excluded due to barriers in communication or navigation.

At Pinnacle Signage, we believe in the power of well-designed, compliant signage to contribute to a more accessible and equitable Australia.

Your Questions on Braille Signage Answered

What spaces require braille signs in Australia?

In Australia, the National Construction Code (NCC) mandates braille and tactile signage for specific areas to ensure accessibility. This includes identifying sanitary facilities, accessible unisex toilets, spaces with hearing augmentation systems, and exits.

Do I need Grade 1 or Grade 2 Braille?

For signage in Australia, Unified English Braille (UEB) Grade 2 is the standard. Grade 2 uses contractions to save space and allow for quicker reading by experienced braille users.

Can I create my own braille signs?

It is strongly advised against. The specifications for dot height, shape, spacing, and placement are extremely precise and legally mandated. Using a professional manufacturer ensures your signs are compliant, durable, and readable.

Sourcing Compliant Universal Braille Signage

Ensuring your public spaces are accessible and inclusive is a fundamental part of modern building management. To guarantee that signage meets all the complex requirements of Australian Standards, it is essential to work with specialist manufacturers. Experts in this field can provide a wide range of standards-compliant Braille Tactile Signage and assist with custom designs tailored to a facility's specific needs, ensuring every sign is fit for purpose and fully compliant.