From Blind Spots to Bright Ideas: How to Identify Hazards Effectively

The First Step to a Safer Workplace

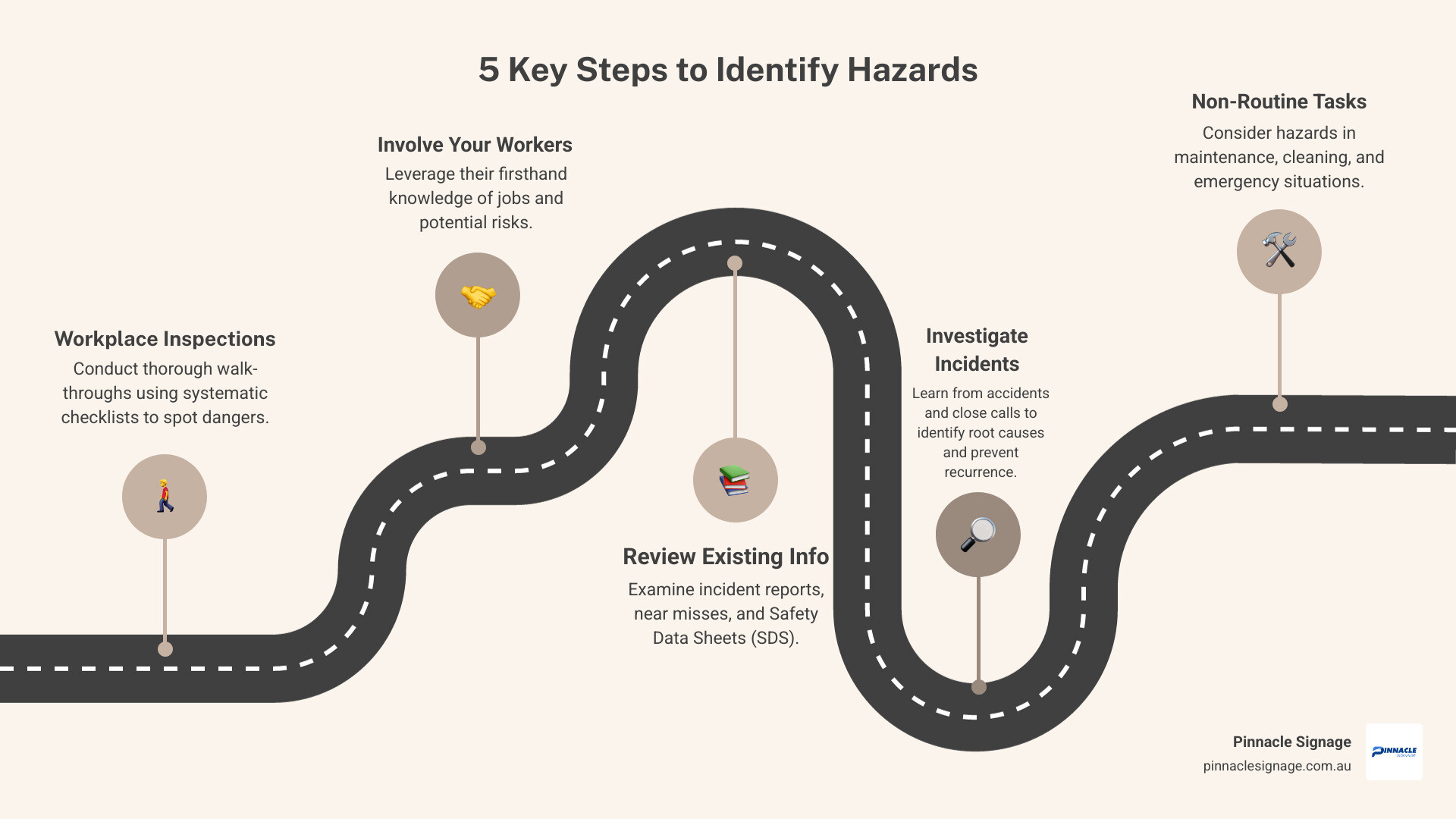

How to identify hazards is the foundation of any effective workplace safety program. Here's your quick guide:

- Conduct workplace inspections - Walk through all areas with a systematic checklist

- Involve your workers - They know their jobs and potential risks best

- Review existing information - Check incident reports, near misses, and Safety Data Sheets

- Investigate all incidents - Learn from both accidents and close calls

- Consider non-routine tasks - Include maintenance, cleaning, and emergency situations

- Document everything - Keep records of hazards found and actions taken

A hazard is any source of potential damage or harm to someone or something in your workplace. The difference between a hazard and risk is simple: a hazard is the source of harm (like a wet floor), while risk is the chance of that harm actually occurring (someone slipping on that wet floor).

Failing to identify or anticipate hazards is a root cause of many workplace injuries, illnesses, and incidents. This makes hazard identification a proactive process—spotting problems before they cause harm, not just reacting after an injury.

Involving your team is crucial, as workers know their jobs and its hazards best. Combining their on-ground experience with systematic inspection processes creates a comprehensive approach to workplace safety that catches both obvious and hidden dangers.

Years of experience in the safety and industrial supply space have shown that effective hazard identification prevents serious incidents and saves lives. Understanding how to identify hazards properly is central to helping Australian businesses create safer workplaces through better signage and safety systems.

A Practical Guide on How to Identify Hazards

Effective hazard identification requires a systematic approach. It’s more than spotting obvious dangers; it’s about developing an eye for potential problems before they cause harm. Think of it as ongoing detective work, searching for clues that something could go wrong. Since workplaces constantly change, new hazards can emerge at any time.

Know What You're Looking For: The 6 Main Hazard Categories

Understanding the different types of hazards helps you cast a wider net when searching for potential problems. Each category has its own characteristics, so knowing what to look for makes all the difference.

Safety hazards are the most visible threats that can cause immediate injury. Think of loose handrails, frayed electrical cords, unguarded machinery, and electrical faults. Slips, trips, and falls are a major concern. For help spotting fire dangers, our guide on All About Fire Hazard Signs: How to Identify Them is a great resource.

Physical hazards can be trickier, as their effects build up over time. Examples include harmful noise levels, extreme temperatures, radiation, and vibration from equipment. These often require measurement tools to identify properly and are sometimes overlooked.

Chemical hazards are more common than you might think, including industrial chemicals and everyday cleaning agents, solvents, or pesticides. The key is knowing what's in your workplace and its potential effects. Our guide Know Your Hazard Symbols: A Guide to Chemical Signage helps decode these warnings.

Biological hazards have always been a risk in many workplaces. They include viruses, bacteria, mould in damp areas, and contaminated waste. They can be found in healthcare, food service, and even office buildings.

Ergonomic hazards develop slowly, making them particularly insidious. They result from manual handling of heavy items, repetitive tasks, and poor workstation design, leading to injuries that build up over months or years.

Psychosocial hazards are a newer focus in workplace safety. These include workplace stress, bullying, fatigue, and tight deadlines. They affect mental health and can lead to mistakes and accidents.

Your Toolkit for Finding Hazards: Key Methods for How to Identify Hazards

Successfully identifying hazards requires the right tools and techniques. Using them together gives you the complete picture.

Workplace inspections are the backbone of hazard identification. These are systematic examinations, not casual walk-throughs. Use walk-throughs for all areas, including storage and maintenance spaces. Checklists ensure nothing is missed, but also observe tasks as they are actually performed. Document everything, using photos to track problems and improvements.

Involving your team is essential. Workers know best what happens in their daily tasks. Use regular safety meetings for formal discussions, but also foster a culture where workers feel comfortable reporting concerns anytime. Anonymous surveys can uncover issues workers might hesitate to mention in person.

Reviewing existing information helps you learn from the past. Review incident reports and near misses. Safety Data Sheets (SDS) provide crucial information on chemical hazards. Resources from Safe Work Australia can help you use this information effectively. Also, check workers' compensation records for trends.

Investigating incidents means digging deeper than the immediate cause using root cause analysis. Ask "why" multiple times. Was it operator error, or was training inadequate? Did equipment fail due to poor maintenance? Learning from mistakes prevents them from recurring.

Planning for non-routine tasks often reveals hidden hazards. Maintenance can involve confined spaces or disabled safety systems. Cleaning may use different chemicals, and emergency situations create unique hazards that need to be anticipated.

Shared Responsibility: Roles in How to Identify Hazards

Effective hazard identification is a shared responsibility that extends throughout the entire organisation.

Employer duties start with providing a safe workplace. This means implementing systematic processes to identify hazards, providing training, creating easy reporting systems, investigating reported hazards promptly, and fostering a positive safety culture.

Supervisor duties bridge the gap between management and workers. They train workers on specific hazards, enforce procedures, and monitor work areas for emerging risks. They must also model safe behaviour themselves.

Worker duties centre on taking reasonable care for their own safety and that of their colleagues. This means reporting hazards, following procedures, and using PPE correctly. Understanding visual cues from signs is also key, as explained in our guide on How to Use Health and Safety Signs in the Workplace Effectively.

From Identification to Action: What to Do Next

How to identify hazards is just the beginning. Once you've spotted potential dangers, the real work starts: assessing risks, implementing controls, and keeping safety front and centre in your daily operations.

Making Hazard Identification an Ongoing Process

Your workplace is always changing, so continuous improvement is essential. Schedule regular reviews, like quarterly safety check-ups, to keep your hazard identification relevant. It's crucial to be adapting to change. Assess hazards before introducing new equipment or new processes, not after an incident. The goal is fostering a safety culture where hazard identification is part of your workplace DNA and reporting concerns is encouraged.

Common Mistakes to Avoid in Hazard Identification

Even well-intentioned safety programs can miss the mark. Here are some common traps to avoid.

- Overlooking non-routine tasks - Many focus on daily work but forget about maintenance, cleaning, or emergencies, which often carry the highest risks.

- Ignoring 'minor' hazards - Small problems, like an uneven tile or a stray cable, can lead to serious incidents.

- Poor worker consultation - Not involving your team means wasting your best resource. They know their jobs and the real-world problems.

- Inadequate documentation - Without records of hazards and actions, you can't track patterns or show how problems were resolved.

- Failing to follow up - If reported concerns are ignored, workers will stop reporting them, killing your safety culture.

Using Signage to Communicate and Control Hazards

Once you've identified hazards, effective signage becomes your silent, 24/7 safety supervisor.

- Visual warnings grab attention when it matters most, alerting workers to wet floors, high voltage, or chemical hazards.

- Reinforcing procedures through signage for PPE, restricted areas, or emergency exits keeps safety practices top-of-mind.

- Guiding actions with clear directions to eyewash stations or fire extinguishers is crucial during emergencies. Our The Definitive Guide to Safety Sign Hazard Identification explores this in much greater detail.

At Pinnacle Signage, we know effective hazard communication requires the right signs in the right places. Our signs are made to last in Australia's tough conditions, from scorching Queensland summers to Melbourne's unpredictable weather, ensuring your safety messages remain clear.

From our Wagga Wagga base, we work with businesses across Australia, providing custom solutions for your specific hazard identification needs. Whether you need clear chemical warnings, emergency guidance, or industry-specific safety alerts, we have the expertise to help.

Ready to turn your hazard identification into effective hazard communication? Explore our comprehensive range:

When you combine thorough hazard identification with clear, professional signage, you're not just ticking safety boxes – you're building a workplace where everyone can focus on doing their best work, knowing they're protected.